The Releated Products of Wire Saw Diamond Blade

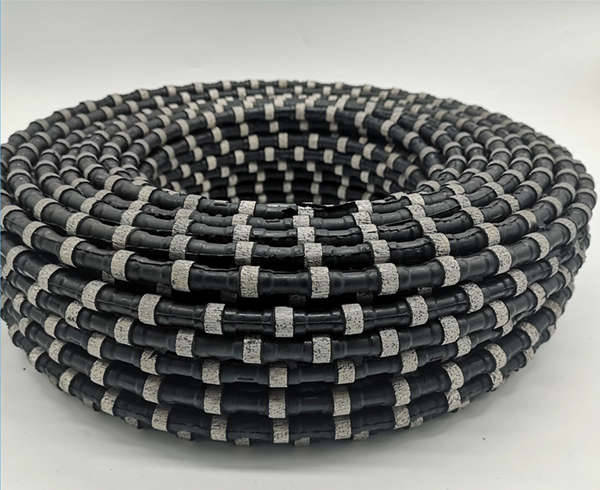

Wire Saw Diamond Blade

Understanding the Precision of Wire Saw Diamond Blades

In the realm of cutting tools, precision and efficiency are paramount. Among the various tools used for cutting hard materials, wire saw diamond blades stand out for their exceptional performance. These specialized tools are designed to cut through dense materials like concrete, stone, and reinforced metals with unparalleled accuracy. Whether you’re involved in construction, mining, or manufacturing, understanding the intricacies of wire saw diamond blades can significantly enhance your operations.

The Composition of Wire Saw Diamond Blades

Wire saw diamond blades consist of a thin, flexible wire embedded with diamond particles. These diamonds act as the cutting edges, making the blade capable of slicing through tough materials with ease. The core material of the wire is typically steel, providing strength and durability while maintaining flexibility necessary for maneuvering around complex shapes and structures. The diamond segments are either electroplated onto the wire or sintered, depending on the application requirements and desired lifespan of the blade.

Applications of Wire Saw Diamond Blades in Construction

In construction projects, wire saw diamond blades offer several advantages over traditional cutting methods. Their ability to make precise cuts without causing significant vibration or noise pollution makes them ideal for working in sensitive areas. They are particularly useful for cutting large slabs of concrete, which is common when demolishing old buildings or remodeling existing structures. Additionally, they can be used to create openings in walls, floors, and ceilings with minimal disturbance to the surrounding area.

Advantages of Using Wire Saw Diamond Blades

The primary advantage of using wire saw diamond blades is their precision. Unlike circular saws or other cutting tools, these blades can achieve straight, clean cuts with minimal material loss. This characteristic is especially beneficial when working with expensive materials where wastage needs to be minimized. Moreover, because the wire is continuously fed through the material being cut, it can handle cuts of any depth, unlike fixed-blade systems that have limited cutting depths.

Maintenance and Care of Wire Saw Diamond Blades

To ensure optimal performance and longevity of your wire saw diamond blades, proper maintenance is essential. After each use, inspect the wire for any signs of wear or damage. Clean the blade thoroughly to remove debris that could interfere with its operation or cause premature wear. Store the blades in a dry place away from extreme temperatures and direct sunlight, which can degrade the materials over time. Regular maintenance will not only extend the life of your blades but also maintain their cutting efficiency.

Selecting the Right Wire Saw Diamond Blade

Choosing the appropriate wire saw diamond blade depends largely on the material you plan to cut and the specific requirements of your project. Factors such as the hardness of the material, the size of the cut, and the level of precision needed all play into selecting the best tool for the job. For softer materials, a blade with fewer and larger diamonds might be sufficient. Harder materials require more densely packed diamonds for effective cutting. Consulting with a specialist can help guide you toward the most suitable option for your needs.

By investing in high-quality wire saw diamond blades and following best practices for their use and care, professionals across industries can achieve superior results in their projects. These versatile tools continue to revolutionize how we approach challenging cutting tasks, setting new standards for efficiency and precision in the field.

Request for Quotation

报错: 未找到这个表单