The Releated Products of Wire Diamond Cutting Saw

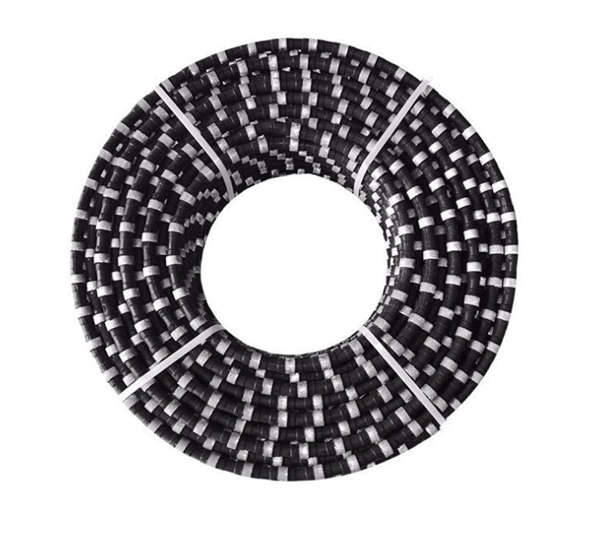

Wire Diamond Cutting Saw

Understanding the Precision of Wire Diamond Cutting Saws

In the realm of industrial cutting tools, precision and efficiency are paramount. One such tool that has revolutionized the way hard materials are cut is the wire diamond cutting saw. This innovative technology utilizes a thin, flexible wire embedded with diamond particles to slice through materials with unparalleled accuracy. Whether you’re working with concrete, stone, or reinforced metals, understanding the capabilities and benefits of wire diamond cutting saws can significantly enhance your operations.

The Mechanics of Wire Diamond Cutting Saws

Wire diamond cutting saws operate on a principle that combines mechanical strength with fluid motion. The core component is a wire coated with industrial-grade diamonds. When this wire is set into motion, typically using a pulley system, it creates a cutting action that is both smooth and powerful. Unlike traditional blade-based saws, the wire’s flexibility allows for intricate cuts and shapes, making it ideal for complex projects where precision is key.

Applications of Wire Diamond Cutting Saws

From construction sites to specialized manufacturing processes, wire diamond cutting saws find application across various industries. They excel particularly in scenarios requiring the cutting of large slabs of concrete, marble, granite, and other dense materials. The saws’ ability to make precise cuts without causing thermal damage to the material being cut makes them indispensable in high-end fabrication and restoration work.

Advantages of Using Wire Diamond Cutting Saws

One major advantage of wire diamond cutting saws is their minimal impact on the surrounding environment during operation. Unlike conventional cutting methods that produce significant dust and noise pollution, these saws often come equipped with water-cooling systems which help reduce dust emission while also cooling the diamond segments for longevity. Additionally, the reduced force required for cutting means less vibration transfer, leading to improved safety conditions for operators.

Maintenance and Care of Wire Diamond Cutting Saws

To ensure optimal performance and longevity of your wire diamond cutting saw, regular maintenance is essential. This includes inspecting the wire for any signs of wear or damage before use. Proper storage when not in use, keeping it away from corrosive substances, and cleaning after every project will help maintain its cutting efficiency. Lubricating moving parts regularly can further prevent rust and extend the life of your equipment.

Choosing the Right Wire Diamond Cutting Saw

Selecting the appropriate wire diamond cutting saw depends largely on the specific requirements of your project. Factors such as the hardness of the material being cut, desired speed of operation, and budget constraints all play a role in determining the best model for you. Consulting with experienced professionals or manufacturers can provide valuable insights into choosing a saw that meets your needs effectively.

Future Innovations in Wire Diamond Cutting Technology

As technology continues to evolve, so too does the design and functionality of wire diamond cutting saws. Advances in diamond coating techniques, alongside improvements in motor efficiency and control systems, promise even greater precision and durability in future models. Keeping abreast of these developments ensures that users remain at the forefront of innovation, capable of tackling increasingly complex tasks with ease.

By embracing the power and versatility of wire diamond cutting saws, businesses can achieve new levels of productivity and quality in their work. Whether you’re a seasoned professional or just starting out, investing in this cutting-edge technology is sure to pay dividends in terms of both efficiency and craftsmanship.

Request for Quotation

报错: 未找到这个表单