The Releated Products of Will A Meta Reciprocating Saw Scar Ceramic

Will A Meta Reciprocating Saw Scar Ceramic

Table of Contents

Will A Meta Reciprocating Saw Scar Ceramic?

When it comes to cutting through various materials, a reciprocating saw is a versatile tool that many professionals and DIY enthusiasts rely on. However, when dealing with delicate materials such as ceramic, the question arises: will a meta reciprocating saw scar ceramic? This article delves into the intricacies of using a reciprocating saw on ceramics, providing insights and tips to ensure precision and safety.

Can A Meta Reciprocating Saw Damage Ceramic Tiles?

Ceramic tiles are known for their durability and aesthetic appeal. Yet, they can be susceptible to damage if not handled properly. A meta reciprocating saw, with its powerful motor and aggressive cutting action, poses a significant risk to the integrity of ceramic surfaces. The high-speed back-and-forth motion of the blade can easily cause chipping, cracking, or even breaking of the tile. Therefore, it’s essential to consider alternative tools designed specifically for cutting ceramics.

Using A Meta Reciprocating Saw On Ceramic: Risks Involved

Attempting to cut ceramic with a reciprocating saw can lead to several issues. First, the blade’s design is not optimized for smooth cuts on hard, brittle materials like ceramics. This mismatch often results in jagged edges and splintering, which not only diminishes the appearance of the finished product but also increases the likelihood of accidents during installation. Moreover, the dust generated from cutting ceramics with a reciprocating saw can be hazardous if proper safety measures are not taken.

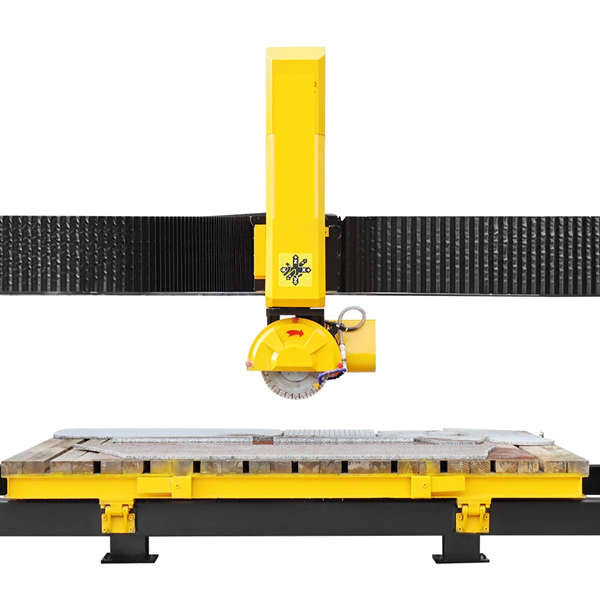

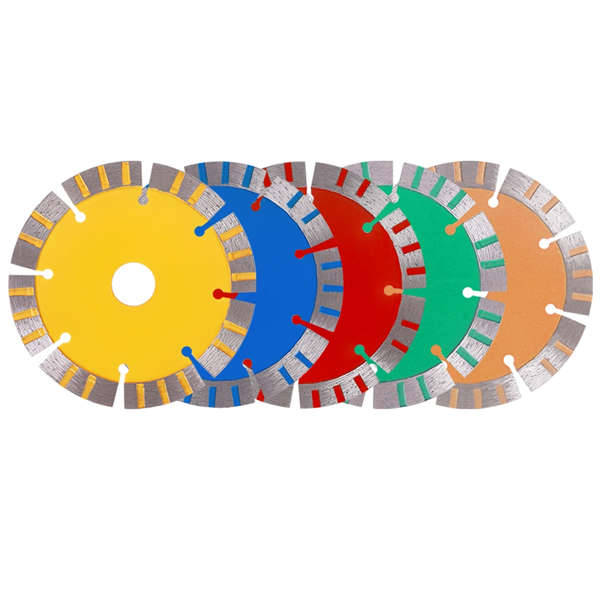

Alternatives To A Meta Reciprocating Saw For Cutting Ceramic

For precise and clean cuts on ceramic materials, specialized tools are recommended. Tile cutters, wet saws, and diamond blades are among the best options available. These tools provide more control over the cutting process, ensuring smoother edges and minimizing the risk of damaging the material. When selecting a tool, consider factors such as the thickness of the ceramic, the type of finish you desire, and your level of experience with DIY projects.

Safety Precautions When Dealing With Ceramic And A Meta Reciprocating Saw

If you must use a reciprocating saw for cutting ceramic, take extensive safety precautions. Wear protective gear including goggles, gloves, and a dust mask to shield yourself from flying debris and harmful particles. Additionally, secure the ceramic piece firmly to prevent movement during the cutting process, which could lead to uneven cuts or slips that might cause injury.

Maintenance Of Tools Used For Cutting Ceramic

Proper maintenance of your cutting tools is crucial for maintaining their efficiency and prolonging their lifespan. Regularly inspect your blades for signs of wear and tear, and replace them as needed. Keep the tool clean and store it in a dry place to prevent rust and corrosion. By taking good care of your equipment, you ensure that it remains effective for future projects involving ceramic materials.

Final Thoughts On Using A Meta Reciprocating Saw With Ceramic

While a reciprocating saw offers versatility in tackling different materials, it may not be the ideal choice for working with ceramic. Understanding the limitations of this tool when applied to ceramics can help you make informed decisions about which tools to use for specific tasks. Always prioritize safety and quality outcomes by choosing the right equipment for the job at hand.

In conclusion, while it might be tempting to use a meta reciprocating saw for all cutting tasks due to its robust nature, recognizing its potential to scar ceramic surfaces is key to achieving professional-grade results. By opting for specialized tools and following best practices, you can enjoy seamless, damage-free cuts every time.

Request for Quotation

报错: 未找到这个表单