The Releated Products of What Is A Diamond Wire Saw

What Is A Diamond Wire Saw

Table of Contents

What Is A Diamond Wire Saw: Precision Cutting in Hard Materials

When it comes to cutting through extremely hard materials such as concrete, stone, or reinforced steel, traditional saws often fall short. This is where diamond wire saws come into play. These specialized tools offer unparalleled precision and efficiency, making them indispensable in industries ranging from construction to gemstone processing. In this article, we’ll explore what a diamond wire saw is, how it works, its applications, and why it’s preferred over other cutting methods.

Diamond Wire Saw Basics: An Overview

A diamond wire saw consists of a thin metal cable embedded with synthetic diamonds. These diamonds act as cutting agents, allowing the saw to slice through tough materials with minimal effort. The wire is typically made of steel and can vary in diameter depending on the application. Larger wires are used for cutting thicker materials, while thinner wires are ideal for more detailed work.

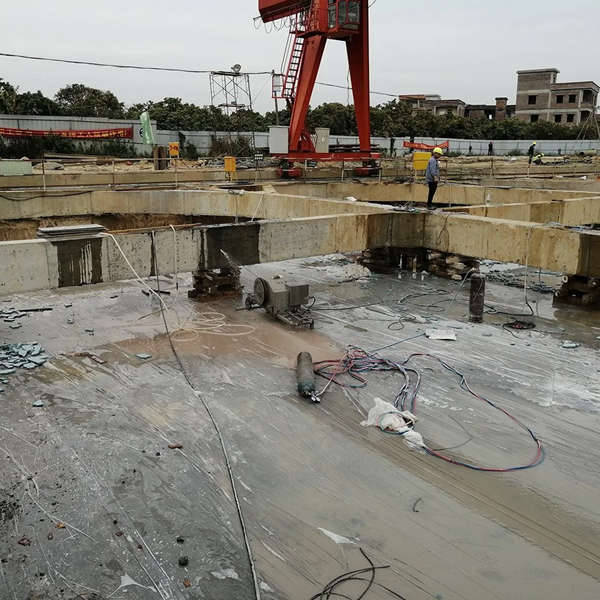

The saw operates by moving the wire at high speeds between two or more pulleys. One of these pulleys is driven by a motor, causing the continuous loop of wire to rotate rapidly. As the wire passes over the material being cut, the embedded diamonds grind away at the surface, creating a clean and precise cut.

How Does A Diamond Wire Saw Work?

Understanding the mechanics behind a diamond wire saw reveals why it’s so effective for demanding tasks. When the motor turns, it causes the wire to move continuously, ensuring that the cutting action is smooth and consistent. Water is usually applied to the cutting area to cool the wire and wash away debris, preventing overheating and ensuring longevity of the tool.

The abrasive nature of the diamonds allows the saw to cut through materials that would otherwise be too challenging for conventional saws. This makes diamond wire saws particularly useful in scenarios requiring high precision, such as in the fabrication of granite countertops or when performing controlled demolition in urban areas.

Applications Of A Diamond Wire Saw

The versatility of diamond wire saws makes them suitable for a wide range of applications. In construction, they are used for cutting large slabs of concrete or removing sections of walls without damaging surrounding structures. For stonemasons, these saws enable intricate designs and smooth finishes that enhance the aesthetic appeal of natural stones.

In the mining industry, diamond wire saws are employed to extract gemstones and minerals from rock formations with minimal damage to the valuable materials. This method ensures higher yields and better quality products compared to traditional blasting techniques.

Benefits And Advantages Of Using A Diamond Wire Saw

One of the key benefits of using a diamond wire saw is its ability to make precise cuts in any direction, even vertically. This flexibility is crucial in projects where accuracy is paramount. Additionally, because the wire can be very thin, it minimizes material loss during cutting, which can lead to significant cost savings especially when working with expensive materials like marble or quartz.

Another advantage is the reduced noise and dust production compared to other cutting methods. This not only creates a safer working environment but also complies with stricter environmental regulations in many regions.

Choosing The Right Diamond Wire Saw For Your Project

Selecting the appropriate diamond wire saw depends on several factors including the type of material being cut, the required depth of cut, and the specific project requirements. Professionals must consider the wire’s grit size, which determines its cutting speed and finish quality. Thicker wires with coarser grit are generally better suited for cutting harder materials or deeper cuts, whereas finer grits provide smoother finishes on softer materials.

Moreover, the power source of the saw (electric vs. hydraulic) and the length of the wire are also important considerations. Electric models are more portable and easier to use in confined spaces, while hydraulic systems deliver more power for larger-scale operations.

Conclusion

In conclusion, diamond wire saws represent a significant advancement in cutting technology, offering unmatched precision and efficiency. Whether you’re involved in construction, stonemasonry, or mineral extraction, investing in a high-quality diamond wire saw can significantly improve productivity and end-product quality. By understanding the basics, mechanics, and applications of these tools, professionals can make informed decisions that enhance their capabilities and expand their service offerings.

Request for Quotation

报错: 未找到这个表单