The Releated Products of Wet Saw For Rocks

Wet Saw For Rocks

Table of Contents

The Precision and Power of Wet Saws for Rocks: A Comprehensive Guide

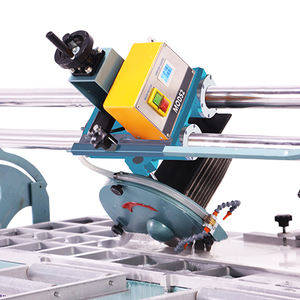

Wet saws for rocks have become indispensable tools in the world of geology, lapidary work, and stonemasonry. These specialized machines allow for precise cutting of hard materials like stone, concrete, and even some metals. By using water to cool the blade and suppress dust, wet saws offer a cleaner, safer, and more efficient cutting experience compared to dry cutting methods. Whether you’re a professional craftsman or an enthusiastic hobbyist, understanding the features and benefits of wet saws for rocks can greatly enhance your projects.

Choosing the Right Wet Saw For Rocks

When it comes to selecting a wet saw for rocks, several factors should be considered to ensure you get the most suitable tool for your needs. First, think about the size and type of material you’ll be cutting. For larger stones, a wet saw with a bigger blade diameter will be necessary. Additionally, look for models equipped with diamond blades, as these are specifically designed to handle abrasive materials such as granite or marble. Lastly, consider the water flow system; a continuous water supply is crucial in maintaining optimal cutting conditions and prolonging the life of your blade.

Benefits of Using a Wet Saw For Rocks

Using a wet saw for rocks provides numerous advantages over traditional dry cutting techniques. One of the primary benefits is the reduction in airborne dust, which not only creates a cleaner working environment but also minimizes health risks associated with inhaling silica particles. Moreover, the cooling effect of water on the blade prevents overheating, ensuring smoother cuts and extending the lifespan of the blade. This results in higher precision and efficiency, making wet saws ideal for detailed work such as creating custom stone countertops or intricate jewelry pieces.

Maintenance Tips for Your Wet Saw For Rocks

Proper maintenance is key to keeping your wet saw for rocks in top condition. Regular cleaning of the water reservoir and pump helps prevent clogging and ensures a steady flow of water during operation. It’s also important to inspect the blade regularly for signs of wear or damage. A dull or damaged blade can lead to poor cut quality and increased risk of accidents. Replacing worn-out blades promptly will maintain the performance and safety of your wet saw. Lastly, storing your wet saw in a dry place when not in use protects its electrical components from moisture damage.

Techniques for Cutting With a Wet Saw For Rocks

To achieve the best results when using a wet saw for rocks, follow these cutting techniques. Always start by securing the material firmly on the table to prevent movement during the cutting process. Adjust the water flow to ensure constant lubrication of the blade without flooding the workspace. When making cuts, apply steady pressure and allow the weight of the saw to do most of the work. Avoid forcing the blade as this can cause binding or kickback. Gradual, controlled movements will produce cleaner edges and reduce the risk of chipping or cracking.

Safety Precautions When Using a Wet Saw For Rocks

Safety should always come first when operating any power tool, including a wet saw for rocks. Wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and waterproof gloves. Ensure all guards are in place and functioning correctly. Never operate the saw without water running; this could cause the blade to overheat and shatter. Keep children and pets away from the work area, and never leave the saw unattended while it’s running. Following these guidelines will help keep you safe while enjoying the benefits of your wet saw for rocks.

Request for Quotation

报错: 未找到这个表单