The Releated Products of Wet Ceramic Tile Saw

Wet Ceramic Tile Saw

Table of Contents

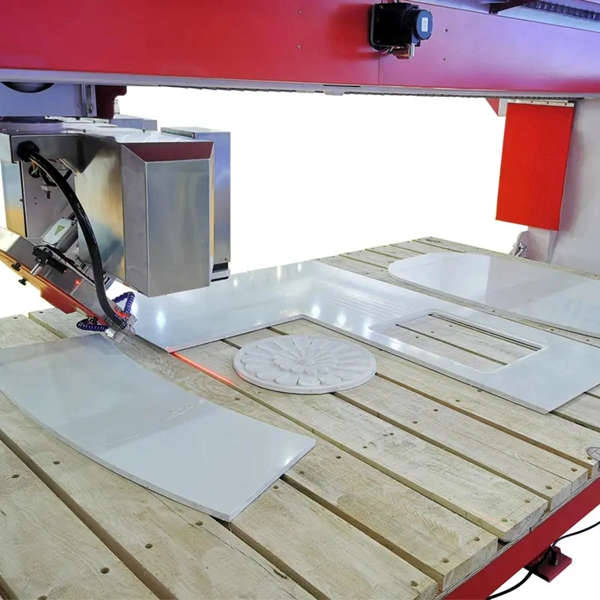

The Precision and Power of Wet Ceramic Tile Saws

Wet ceramic tile saws have become indispensable tools for professionals and DIY enthusiasts tackling intricate tiling projects. These specialized machines offer unmatched precision and efficiency when cutting through tough materials like ceramic and porcelain tiles. This article explores the key features, benefits, and considerations when choosing a wet ceramic tile saw, ensuring you make the best investment for your needs.

Understanding the Basics of Wet Ceramic Tile Saws

Understanding the basics of wet ceramic tile saws is crucial for anyone looking to purchase one. Unlike dry cutters, wet saws use a continuous stream of water to cool the blade and suppress dust, which extends blade life and ensures cleaner cuts. The water also helps maintain the integrity of the material being cut, reducing chipping and cracking.

Key Features of a High-Quality Wet Ceramic Tile Saw

When evaluating wet ceramic tile saws, several key features stand out as essential for delivering optimal performance. A powerful motor, adjustable miter gauge, and a durable frame are among the top considerations. Additionally, look for models that offer easy blade changes and a robust water flow system to keep the cutting area clean and cool.

Benefits of Using a Wet Ceramic Tile Saw

The benefits of using a wet ceramic tile saw extend beyond just the quality of the cut. These saws reduce noise levels significantly compared to their dry counterparts, making them ideal for residential areas. They also minimize airborne particles, creating a safer working environment. Furthermore, wet cutting techniques allow for more complex designs and angles without compromising the tile’s structural integrity.

Maintenance Tips for Your Wet Ceramic Tile Saw

Proper maintenance of your wet ceramic tile saw is vital to ensure longevity and consistent performance. Regularly cleaning the saw, especially the water pump and spray nozzles, prevents clogging and ensures a steady water supply. Checking the blade alignment and tightening all bolts periodically will help maintain accuracy over time. Lastly, storing the saw in a dry place when not in use protects it from rust and corrosion.

Selecting the Right Blade for Your Wet Ceramic Tile Saw

Choosing the right blade for your wet ceramic tile saw can make all the difference in the quality of work produced. Blades come in various sizes and types, designed for different materials and applications. For example, diamond blades are excellent for cutting through hard surfaces such as granite or marble, while turbo-grit blades are better suited for softer stones like limestone. Always match the blade to the specific task to achieve the best results.

Common Issues and Troubleshooting Tips for Wet Ceramic Tile Saws

Despite their robust design, wet ceramic tile saws may encounter issues during operation. Common problems include dull blades, misaligned guides, and clogged water lines. Identifying these issues early on and addressing them promptly can save you both time and money. For instance, replacing a worn-out blade or adjusting the guide rollers can often resolve many cutting inaccuracies.

In conclusion, investing in a high-quality wet ceramic tile saw opens up new possibilities in terms of creativity and craftsmanship. By understanding its features, benefits, and proper maintenance, you’ll be well-equipped to handle any project that comes your way. Whether you’re a seasoned professional or a passionate DIYer, a reliable wet ceramic tile saw is a valuable addition to any workshop.

Request for Quotation

报错: 未找到这个表单