The Releated Products of Water Jet Cutting Marble

Water Jet Cutting Marble

Table of Contents

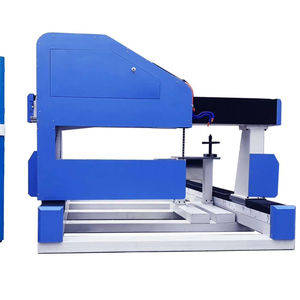

Water Jet Cutting Marble: Precision, Power, and Possibilities

In the world of stone cutting, few techniques match the precision and versatility of water jet cutting marble. This advanced technology uses a high-pressure stream of water mixed with abrasive particles to cut through even the hardest materials, including marble. With its ability to achieve intricate designs and seamless cuts, water jet technology has revolutionized the way we approach marble fabrication. Let’s explore the benefits, applications, and nuances of using water jet cutting for marble.

Water Jet Cutting Marble: An Introduction

Water jet cutting marble is a process that harnesses the power of ultra-high-pressure water jets (up to 60,000 psi) combined with an abrasive such as garnet. The water jet is capable of cutting marble without generating heat, which means there’s no risk of thermal damage to the material. This makes it ideal for creating detailed sculptures, architectural elements, and decorative pieces from marble.

Benefits of Using Water Jet Cutting for Marble

The advantages of using water jet cutting on marble are numerous. Firstly, it offers unparalleled accuracy, allowing for the creation of complex shapes and designs that would be nearly impossible with traditional methods. Additionally, water jet cutting produces cleaner edges with less chipping or cracking compared to other cutting techniques. Lastly, it’s a more environmentally friendly option since it minimizes dust and noise pollution.

Applications of Water Jet Cutting Marble

From countertops and flooring to intricate statues and decorative panels, water jet cutting marble opens up endless possibilities in design and construction. Architects and designers can now push the boundaries of creativity, incorporating detailed patterns and custom logos directly into marble surfaces. This method also allows for combining different materials seamlessly within a single piece, enhancing aesthetic appeal and functionality.

Process of Water Jet Cutting Marble

The process begins by designing the desired shape or pattern using CAD software. Once finalized, this digital blueprint guides the water jet cutter, ensuring precise execution every time. During operation, a small nozzle forces water and abrasive particles at extremely high pressures against the surface of the marble, gradually eroding it until the specified depth is achieved. Throughout the process, excess water and debris are collected and recycled, making it a sustainable choice.

Maintenance and Care After Water Jet Cutting Marble

After undergoing water jet cutting, marble requires proper maintenance to preserve its beauty and longevity. Regular cleaning with mild soap and water is sufficient for most applications. However, it’s important to avoid harsh chemicals that could damage the surface. For outdoor installations, applying a sealant can help protect against weathering and staining.

Future Trends in Water Jet Cutting Marble

As technology continues to advance, so too does the potential for water jet cutting marble. Innovations in software and machinery are leading to faster processing times, improved efficiency, and even greater precision. Moreover, the integration of artificial intelligence could soon allow for real-time adjustments during cutting, further enhancing the capabilities of this remarkable technique.

Water jet cutting marble represents not just a technological advancement but a creative breakthrough in the field of stone artistry. By combining age-old craftsmanship with modern innovation, artisans can now bring their visions to life like never before. Whether you’re an artist seeking new mediums for expression or a business owner looking to add a touch of elegance, exploring what water jet cutting can do for your marble projects is worth considering.

Request for Quotation

报错: 未找到这个表单