The Releated Products of Using Table Saw To Cut Ceramic Tile

Using Table Saw To Cut Ceramic Tile

Table of Contents

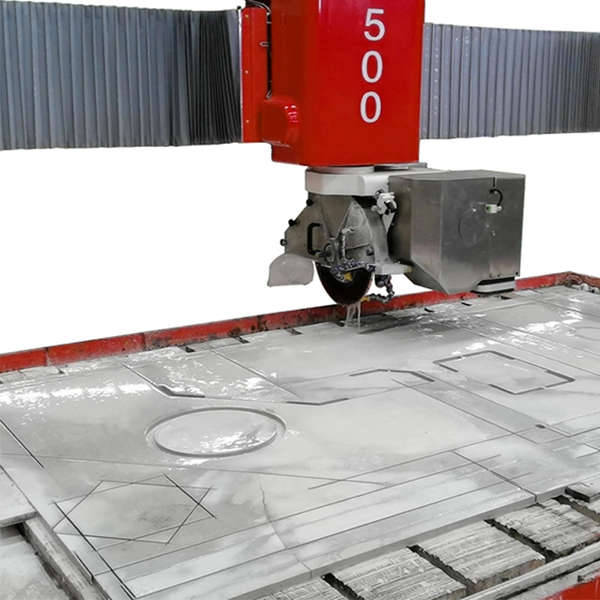

Using a Table Saw to Cut Ceramic Tile: Precision and Efficiency

When it comes to home renovation or DIY projects, cutting ceramic tile can be one of the most challenging tasks. Traditional methods like using a manual tile cutter might not always yield the desired results, especially for intricate cuts or large-scale projects. This is where a table saw designed for cutting ceramic tile can significantly enhance your project’s outcome. Not only does it offer precision and efficiency, but it also allows for more complex designs and faster completion times.

Choosing the Right Table Saw for Cutting Ceramic Tile

Selecting the appropriate table saw is crucial for achieving clean, precise cuts when working with ceramic tiles. Look for a model that features a diamond blade specifically designed for cutting ceramics and other hard materials. These blades are more durable and provide smoother edges compared to standard metal-cutting blades. Additionally, ensure your table saw has a water cooling system to keep the blade from overheating and potentially damaging the tile.

Setting Up Your Table Saw for Cutting Ceramic Tile

Before you begin cutting, it’s essential to set up your table saw correctly. Start by ensuring the surface is level and stable, which helps maintain accuracy during the cutting process. Adjust the fence so that it guides the tile straight through the blade, minimizing any risk of chipping or breaking. Lastly, fill the water reservoir if your saw has a wet cutting feature; this will help reduce dust and prolong the life of your diamond blade.

Tips for Cutting Ceramic Tile with a Table Saw

Using a table saw to cut ceramic tile requires some technique and practice. Always wear protective gear such as safety glasses and ear protection. Mark your tiles clearly with a pencil before placing them on the saw bed. Slow and steady movements produce better results; rushing can lead to uneven cuts or breakage. If possible, make test cuts on scrap pieces to get comfortable with the process before tackling your main project.

Maintaining Your Table Saw for Cutting Ceramic Tile

Proper maintenance of your table saw is key to ensuring long-term performance and reliability, especially when used frequently for cutting ceramic tile. Regularly clean the saw to remove any tile dust or debris that may accumulate. Inspect the diamond blade periodically for wear or damage; a dull blade can cause rough cuts and increase the likelihood of tile breakage. Keep the water supply system clean and functioning to prevent clogs or leaks.

Advantages of Using a Table Saw to Cut Ceramic Tile

Compared to traditional methods, using a table saw offers several advantages when cutting ceramic tile. It provides greater control over the cutting process, allowing for more accurate and consistent cuts. The ability to perform miter cuts or bevels adds versatility to your projects, enabling creative design options. Moreover, wet cutting reduces airborne dust, creating a safer work environment.

Safety Considerations When Using a Table Saw for Ceramic Tile

While using a table saw for cutting ceramic tile can be highly effective, it’s important to prioritize safety. Never force the tile through the blade; allow the saw to do the work. Keep fingers away from moving parts and use push sticks or blocks whenever possible. Familiarize yourself with all safety features of your saw, including emergency stop buttons and blade guards. By following these guidelines, you can enjoy a safe and productive cutting experience.

By embracing the use of a table saw for cutting ceramic tile, DIY enthusiasts and professionals alike can elevate their projects to new heights. With the right tools, setup, and techniques, even complex tiling jobs become manageable and rewarding.

Request for Quotation

报错: 未找到这个表单