The Releated Products of Used Marble Cutting Machine

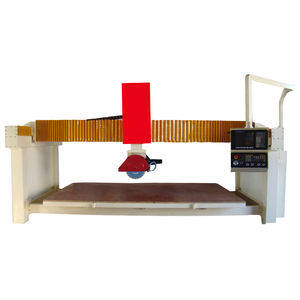

Used Marble Cutting Machine

Table of Contents

Used Marble Cutting Machine: A Cost-Effective Solution for Your Business

In the world of stone fabrication, precision and efficiency are paramount. Investing in high-quality equipment can significantly enhance productivity while reducing operational costs. One such investment is a used marble cutting machine. These machines offer a viable alternative to new models, providing similar performance at a fraction of the cost. This article explores the benefits, considerations, and tips on purchasing a used marble cutting machine.

Benefits of Using a Used Marble Cutting Machine

The primary advantage of opting for a used marble cutting machine lies in its affordability. Businesses can acquire top-tier technology without breaking the bank, allowing them to allocate funds towards other critical areas like marketing or expanding product lines. Additionally, these machines often come with warranties from reputable dealers, ensuring peace of mind for buyers.

Factors to Consider When Buying a Used Marble Cutting Machine

Before making a purchase, it’s essential to consider several factors. First, assess the condition of the machine. Look for signs of wear and tear, especially on components that affect performance, such as the blade and motor. Secondly, verify the machine’s maintenance history. Regular upkeep is crucial for maintaining optimal functionality. Lastly, ensure compatibility with existing systems and materials being cut.

How to Inspect a Used Marble Cutting Machine

A thorough inspection is vital when considering a used marble cutting machine. Start by checking the overall build quality and stability. Loose parts or excessive vibrations during operation indicate potential issues. Next, focus on the cutting mechanism. The blade should be sharp and properly aligned. Electrical components must also be in good working order, free from damage or corrosion.

Maintenance Tips for a Used Marble Cutting Machine

Proper maintenance extends the lifespan of a used marble cutting machine and ensures consistent performance. Regular cleaning prevents dust and debris buildup, which can interfere with cutting accuracy. Lubricating moving parts reduces friction and wear. Lastly, follow the manufacturer’s guidelines for blade replacement and calibration to maintain cutting precision.

Where to Find a Reliable Used Marble Cutting Machine

Several options exist for sourcing reliable used marble cutting machines. Local dealers often carry a variety of models from different brands, offering both sales and service support. Online marketplaces provide access to a wider range of choices, though buyers should exercise caution to avoid scams. Directly contacting manufacturers can also yield good deals on refurbished units backed by warranty coverage.

Conclusion

A used marble cutting machine represents a smart investment for businesses looking to improve their stone cutting capabilities without the hefty price tag associated with new equipment. By carefully considering the factors mentioned above, conducting a thorough inspection, and maintaining the machine properly, you can enjoy years of efficient, accurate cutting. Whether you’re just starting out or expanding your operations, a used marble cutting machine could be the perfect addition to your workshop.

Request for Quotation

报错: 未找到这个表单