The Releated Products of Used Machine Diamond Wire Saw

Used Machine Diamond Wire Saw

Table of Contents

Used Machine Diamond Wire Saw: A Comprehensive Guide

In the realm of construction and industrial cutting, precision and efficiency are paramount. One tool that has revolutionized the industry is the diamond wire saw. Specifically, used machine diamond wire saws offer a cost-effective solution without compromising on performance. This article delves into the world of these powerful tools, exploring their benefits, applications, and considerations when purchasing.

Advantages of Used Machine Diamond Wire Saws

When considering the acquisition of a diamond wire saw, opting for a used machine can provide significant advantages. Firstly, cost savings are substantial; high-quality pre-owned machines often come at a fraction of the price of new ones. Additionally, these tools maintain their cutting prowess, ensuring that projects are completed with the same level of accuracy and speed as their brand-new counterparts. With proper maintenance records and thorough inspections, a used diamond wire saw can be a reliable investment for any business looking to enhance its cutting capabilities.

Applications of Used Machine Diamond Wire Saws

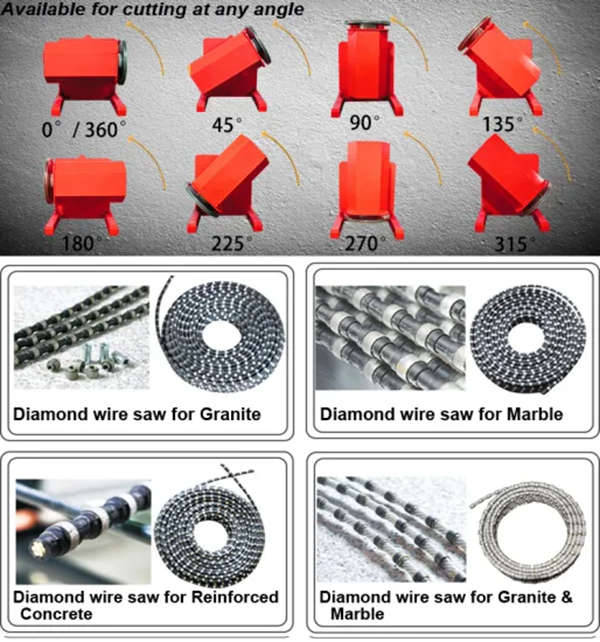

The versatility of diamond wire saws makes them indispensable across various industries. From quarrying and mining to construction and demolition, these machines excel in cutting through dense materials like reinforced concrete, granite, and marble. Used machine diamond wire saws are particularly beneficial for contractors who need robust equipment capable of handling challenging tasks while adhering to tight budgets. Their ability to make precise cuts with minimal vibration or noise pollution also makes them ideal for urban environments where disturbance must be kept to a minimum.

Maintenance Tips for Used Machine Diamond Wire Saws

To ensure longevity and optimal performance from your used diamond wire saw, regular maintenance is crucial. This includes inspecting the wire for wear and tear, checking lubrication levels, and cleaning debris from moving parts. Keeping the machine well-maintained not only extends its life but also enhances safety during operation. It’s advisable to follow the manufacturer’s guidelines closely and invest in professional servicing periodically to identify potential issues early on.

Purchasing Considerations for Used Machine Diamond Wire Saws

When shopping for a used diamond wire saw, several factors should be considered to make an informed decision. Evaluate the condition of the machine thoroughly, paying close attention to the drive unit and wire tension mechanism. Request detailed service history documentation to assess how well the previous owner maintained it. Also, consider compatibility with existing equipment and accessories, ensuring seamless integration into your workflow. Lastly, opt for reputable sellers who offer warranties or guarantees, providing peace of mind post-purchase.

Innovations in Used Machine Diamond Wire Saws

Despite being second-hand, many used diamond wire saws incorporate advanced features that improve productivity and ease of use. Technological advancements such as automatic wire tension control systems and enhanced motor efficiency continue to be integrated into newer models, which can sometimes be found among used inventory. These innovations not only increase cutting speed and precision but also reduce operator fatigue, making them valuable additions to any workshop or job site.

Conclusion on Used Machine Diamond Wire Saws

Investing in a used machine diamond wire saw represents a strategic move for businesses aiming to optimize operations without straining financial resources. By understanding the unique benefits, applications, maintenance requirements, and technological advancements associated with these tools, you can confidently leverage them to propel your projects forward. Whether you’re tackling large-scale construction projects or intricate stonework, a well-chosen used diamond wire saw will undoubtedly prove to be an invaluable asset.

Request for Quotation

报错: 未找到这个表单