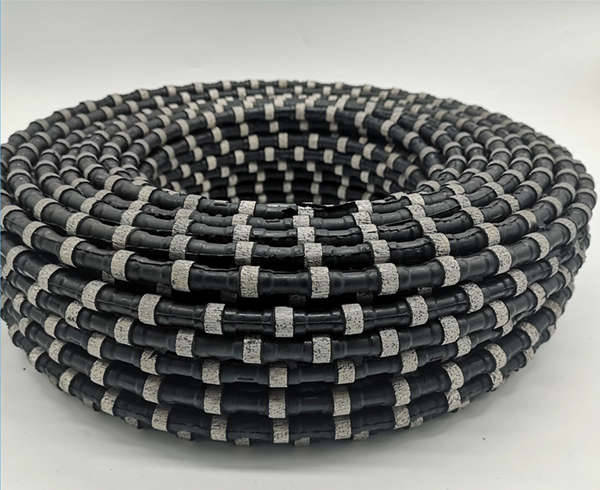

The Releated Products of Used Diamond Wire Saw Machine

Used Diamond Wire Saw Machine

Table of Contents

Understanding the Benefits of Used Diamond Wire Saw Machines

In the realm of construction and mining, precision cutting tools are indispensable. Among these, diamond wire saw machines stand out for their efficiency and versatility. As businesses look to optimize costs without compromising on quality, the demand for used diamond wire saw machines has surged. This article delves into the advantages, applications, and considerations when purchasing such equipment.

Cost-Effectiveness of Used Diamond Wire Saw Machines

Investing in new machinery can be financially straining for many companies, especially small to medium-sized enterprises. Used diamond wire saw machines offer a viable alternative, providing significant cost savings while maintaining high performance standards. These pre-owned machines are often refurbished by reputable dealers, ensuring they meet the same operational criteria as brand-new models. By opting for used equipment, businesses can allocate funds to other critical areas, enhancing overall productivity and profitability.

Maintenance Requirements for Used Diamond Wire Saw Machines

Regular maintenance is crucial for prolonging the lifespan of any mechanical equipment, including diamond wire saw machines. When dealing with used models, it’s essential to understand the specific maintenance needs and schedules. This includes checking the tension of the wire, inspecting for wear and tear, and replacing parts as necessary. Proper care not only ensures safety during operations but also helps maintain optimal cutting performance over time.

Applications of Used Diamond Wire Saw Machines

Diamond wire saw technology is widely applied across various industries due to its ability to cut through hard materials like concrete, stone, and metal with minimal effort. In construction, these machines are invaluable for demolition projects where precision is key. They are also utilized in the quarrying industry for extracting blocks from larger stone formations. For recycling purposes, diamond wire saws help in breaking down large pieces of reinforced concrete or metal, contributing to more sustainable practices.

Selecting the Right Used Diamond Wire Saw Machine

Choosing the appropriate used diamond wire saw machine depends on several factors, including the nature of the work, budget constraints, and desired output quality. It’s advisable to consult with experts who can guide you through the selection process based on your specific requirements. Additionally, consider the availability of spare parts and service support, which are critical for long-term use and reducing downtime.

Environmental Impact of Using Diamond Wire Saw Machines

One often overlooked aspect of using diamond wire saw technology is its environmental footprint. Compared to traditional methods, these machines produce less noise pollution and generate minimal dust and debris. This makes them particularly suitable for urban construction sites where minimizing disruption is paramount. Furthermore, the efficient cutting process reduces material waste, promoting sustainability within the industry.

Training and Safety Considerations for Used Diamond Wire Saw Machines

Safety should always come first when operating any heavy machinery. While used diamond wire saw machines undergo rigorous testing before resale, operators must receive proper training to handle them effectively. Training programs cover everything from basic operation to emergency procedures, ensuring all personnel are well-prepared. Implementing strict safety protocols minimizes risks associated with machine usage, protecting both workers and assets.

By considering these aspects, businesses can make informed decisions about incorporating used diamond wire saw machines into their operations. Whether upgrading existing equipment or entering new markets, these versatile tools represent a smart investment for companies committed to excellence and innovation.

Request for Quotation

报错: 未找到这个表单