The Releated Products of Ultrasonic Stone Cutting

Ultrasonic Stone Cutting

Table of Contents

The Revolutionary Technique of Ultrasonic Stone Cutting

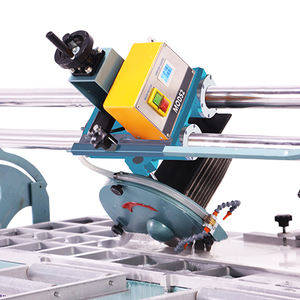

Ultrasonic stone cutting technology has emerged as a game-changer in the industry, offering unparalleled precision and efficiency. This method utilizes high-frequency vibrations to cut through hard materials like stone, glass, and ceramics with minimal effort and maximum accuracy.

Principles Behind Ultrasonic Stone Cutting

Understanding the principles behind ultrasonic stone cutting is crucial for grasping its effectiveness and potential applications. At its core, this process involves generating ultrasonic vibrations that are transmitted through a tool or blade in contact with the material being cut. These vibrations reduce friction and heat, allowing for smoother cuts and less wear on the cutting tool.

Advantages of Ultrasonic Stone Cutting

The advantages of ultrasonic stone cutting are numerous and significant. Firstly, it provides enhanced precision, enabling intricate designs and fine details that would be challenging to achieve with traditional methods. Additionally, the reduced friction leads to lower temperatures, which helps maintain the integrity of both the material being cut and the cutting tool itself. This results in longer tool life and fewer interruptions due to tool replacement or maintenance.

Applications of Ultrasonic Stone Cutting

From sculpting marble statues to crafting delicate jewelry pieces, the applications of ultrasonic stone cutting span across various industries. In construction, it allows for precise cutting of tiles and slabs, reducing waste and improving aesthetics. For artisans and jewelers, this technology opens up new possibilities for creating complex shapes and patterns in hard stones without compromising their structural integrity.

Techniques in Ultrasonic Stone Cutting

Several techniques have been developed to optimize the performance of ultrasonic stone cutting. One such technique involves using water jets alongside ultrasonic vibrations, which not only cools the cutting area but also flushes away debris, providing clearer visibility during the cutting process. Another approach focuses on varying the frequency and amplitude of the vibrations to suit different materials and thicknesses, ensuring optimal cutting efficiency across a wide range of applications.

Challenges in Implementing Ultrasonic Stone Cutting

Despite its many benefits, implementing ultrasonic stone cutting can present certain challenges. The initial investment in equipment and training can be substantial, making it a barrier for smaller operations. Moreover, finding skilled operators who can fully leverage the capabilities of this technology might require time and resources. However, these challenges are increasingly being addressed by advancements in automation and user-friendly design, making the technology more accessible.

Future Prospects of Ultrasonic Stone Cutting

Looking ahead, the future prospects of ultrasonic stone cutting appear promising. As research continues, we can expect improvements in both the hardware and software aspects of this technology. Innovations in material science could lead to even more durable and versatile cutting tools. Furthermore, integration with other advanced manufacturing processes, such as 3D printing, may open up entirely new dimensions in design and production capabilities.

In conclusion, ultrasonic stone cutting represents a significant leap forward in the field of material processing. Its unique combination of speed, precision, and versatility positions it as a key technology shaping the future of industries that rely on cutting hard materials.

Request for Quotation

报错: 未找到这个表单