The Releated Products of Tile Saw Not Cutting Straight

Tile Saw Not Cutting Straight

Troubleshooting Your Tile Saw: Why It’s Not Cutting Straight

Understanding the Basics: Why Your Tile Saw Isn’t Cutting Straight

A tile saw not cutting straight can be frustrating, especially when you’re working on a project that requires precision. This issue can arise from several factors, including improper setup, blade wear, or incorrect use. Identifying the root cause is key to resolving it. Let’s explore some common reasons why your tile saw might be failing to make straight cuts.

Blade Condition: A Major Culprit for Misaligned Cuts

The condition of your blade plays a significant role in how straight your cuts will be. Over time, blades can become dull, misshapen, or even damaged. A worn-out blade lacks the sharpness necessary for clean, precise cuts. To check if this is the problem, inspect your blade for any signs of wear such as chips, dents, or general dullness. If you find any issues, replacing the blade may solve your straight-cutting woes.

Adjusting the Guide: Aligning Your Cuts for Perfection

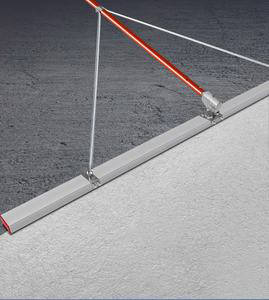

Sometimes, the alignment of the guide on your tile saw can lead to crooked cuts. The guide is responsible for keeping the blade aligned with the intended cut line. If it’s not properly adjusted, it can cause the blade to veer off course. Check the manufacturer’s manual for instructions on how to adjust the guide. Ensuring that the guide is correctly positioned can significantly improve the accuracy of your cuts.

Proper Lubrication: Keeping Your Tile Saw Running Smoothly

Lubrication is essential for maintaining the performance of your tile saw. Without adequate lubrication, the moving parts can become stiff, which might affect the stability of the blade during operation. This can result in uneven cutting. Regularly apply lubricant to the moving parts of your saw, following the manufacturer’s recommendations. This will help ensure smooth operation and reduce the likelihood of jagged edges or wavy cuts.

Blade Tension: Maintaining Optimal Performance for Precision Cuts

For many tile saws, especially those with segmented blades, maintaining proper blade tension is crucial. Loose blades tend to wobble, leading to imprecise cuts. On the other hand, over-tightening can cause the blade to warp or break. Refer to your user manual for guidance on achieving the right level of tension. Adjusting the blade tension could be the simple fix you need to get back to making straight, clean cuts.

Checking the Motor: Power Output and Its Impact on Cutting Quality

If your tile saw is still not cutting straight despite addressing the above issues, the motor might be the problem. Insufficient power can cause the blade to slow down under pressure, leading to wandering cuts. Ensure that the motor is functioning correctly and delivering the required power. In some cases, a motor upgrade might be necessary to handle tougher materials or more demanding projects.

Cleaning the Track: Removing Debris for Better Alignment

Debris buildup on the track can cause your tile saw to cut inaccurately. Dirt, dust, and small particles can interfere with the smooth movement of the blade, causing it to deviate from its path. Regular cleaning of the track is recommended to keep it free from obstructions. Use a soft cloth or brush to remove any dirt, and consider applying a light coat of silicone spray to keep the track running smoothly.

By addressing these potential causes, you can often resolve issues with your tile saw not cutting straight. Remember, regular maintenance and careful attention to detail are key to ensuring your tool performs at its best. If problems persist, consulting a professional or contacting the manufacturer for further assistance might be necessary.

Request for Quotation

报错: 未找到这个表单