The Releated Products of Tile Cutting Equipment

Tile Cutting Equipment

Table of Contents

Tile Cutting Equipment: Precision, Efficiency, and Durability

Tile cutting equipment plays a pivotal role in construction and renovation projects, offering precision and efficiency when it comes to shaping tiles. Whether you’re a professional contractor or a DIY enthusiast, having the right tile cutting tools can make all the difference. This article explores various types of tile cutting equipment, their features, and how they enhance your work.

Tile Cutting Equipment for Ceramic Tiles

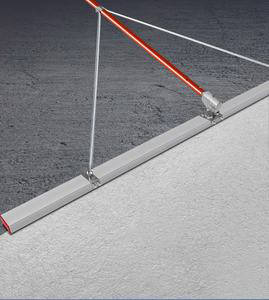

When working with ceramic tiles, choosing the appropriate tile cutting equipment is crucial for achieving clean, precise cuts. Manual tile cutters are popular for smaller projects due to their affordability and ease of use. These tools typically feature a robust steel frame, a scoring wheel, and a breaking mechanism that allows users to score and snap tiles along a straight line. For larger-scale operations, electric wet saws offer unmatched precision and speed. Their water-cooled diamond blades ensure smooth, accurate cuts while minimizing dust and chipping.

Selecting the Right Tile Cutting Equipment

Selecting the right tile cutting equipment depends on several factors, including the type of tiles you’re working with, project size, and your budget. For instance, porcelain tiles require more powerful equipment compared to standard ceramic tiles because of their hardness and density. Porcelain tile cutters often come equipped with stronger motors and larger cutting blades to handle these demanding materials effectively. Additionally, consider whether you need a portable solution for on-site work or a stationary setup for workshop use.

Maintaining Your Tile Cutting Equipment

Proper maintenance is key to extending the lifespan of your tile cutting equipment. Regular cleaning and lubrication of moving parts prevent wear and tear, ensuring optimal performance over time. For wet saws, regularly check and replace the diamond blade as needed to maintain cutting accuracy. Dull blades not only affect the quality of cuts but also increase the risk of chipping or cracking tiles during the cutting process.

Benefits of Using Advanced Tile Cutting Equipment

Advanced tile cutting equipment offers numerous benefits that can significantly improve productivity and reduce waste. Features such as laser guides provide enhanced accuracy, allowing for consistent and repeatable cuts. Adjustable depth settings enable users to make plunge cuts or bevel edges with ease, expanding creative possibilities in tile design. Moreover, ergonomic designs and safety features protect operators from injuries, making these tools indispensable in modern construction sites.

Tile Cutting Equipment Safety Tips

Safety should always come first when operating any kind of power tool, including tile cutting equipment. Always wear personal protective equipment (PPE) like safety glasses, gloves, and hearing protection. Keep the workspace well-lit and free of clutter to avoid accidents. If using a wet saw, ensure adequate ventilation or a dust collection system to minimize inhalation of silica dust, which can be harmful when inhaled.

Investing in Quality Tile Cutting Equipment

Investing in high-quality tile cutting equipment is a wise decision for professionals and serious DIYers alike. While premium tools may come with a higher upfront cost, they offer long-term savings by reducing material waste, increasing efficiency, and producing better results. Look for brands known for durability and customer support to get the most value out of your investment. Remember, the right tool can turn a challenging task into a manageable one, enhancing both the enjoyment and outcome of your tiling projects.

By considering these aspects of tile cutting equipment, you’ll be better prepared to choose the best tools for your needs, ensuring that every project—big or small—is completed with excellence.

Request for Quotation

报错: 未找到这个表单