The Releated Products of Stone Shaping Machine

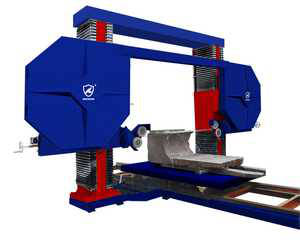

Stone Shaping Machine

Stone Shaping Machine: Crafting Precision and Beauty

In the world of construction and architecture, the role of stone shaping machines cannot be overstated. These machines have revolutionized the way we design, carve, and finish stones, enabling artisans and engineers to achieve levels of precision and creativity previously unattainable. This article explores the multifaceted capabilities of stone shaping machines, highlighting their importance in modern stonework.

Stone Shaping Machine: Precision Cutting

Precision cutting is one of the primary functions of a stone shaping machine. With advanced technologies like computer numerical control (CNC), these machines can cut through even the hardest stones with remarkable accuracy. Whether it’s granite, marble, or limestone, stone shaping machines ensure that every piece is cut to exact specifications, minimizing material waste and maximizing efficiency.

Stone Shaping Machine: Efficient Polishing

The polishing process is critical for bringing out the natural beauty of stones. A stone shaping machine equipped with specialized polishing tools can transform rough surfaces into smooth, glossy finishes. By using abrasive discs of varying grits, these machines gradually refine the surface of the stone until it reaches the desired level of shine. This not only enhances the aesthetic appeal but also improves the durability of the stone.

Stone Shaping Machine: Versatile Carving Capabilities

From intricate sculptures to detailed engravings, the versatility of stone shaping machines in carving is unparalleled. Using a combination of rotary tools and cutting bits, these machines can create complex designs on stone surfaces. This capability opens up endless possibilities for architects and artists looking to add unique decorative elements to their projects. Whether it’s for interior decor or outdoor monuments, stone shaping machines deliver precise and consistent results every time.

Stone Shaping Machine: Safety and Ergonomics

Safety is paramount when operating heavy machinery, especially those designed for stone work. Modern stone shaping machines incorporate various safety features such as emergency stop buttons, protective shields, and automated systems that reduce the risk of accidents. Additionally, ergonomic designs improve user comfort during long hours of operation, making these machines safer and more pleasant to use.

Stone Shaping Machine: Customization Options

One of the most exciting aspects of stone shaping machines is their ability to be customized according to specific project needs. Manufacturers often offer a range of attachments and accessories that can be added to enhance functionality. For instance, adding a water jet cutter allows for cutting delicate materials without causing thermal damage. Such customization ensures that users get exactly what they need from their stone shaping machines, whether it’s for small-scale projects or large industrial applications.

Stone Shaping Machine: Maintenance and Longevity

To ensure optimal performance over time, proper maintenance of stone shaping machines is essential. Regular cleaning, lubrication of moving parts, and timely replacement of worn-out components help maintain the machine’s efficiency. Many manufacturers provide comprehensive maintenance plans and training sessions to educate users on best practices. Investing in quality maintenance not only prolongs the life of the machine but also preserves its cutting-edge capabilities.

By combining traditional craftsmanship with modern technology, stone shaping machines redefine the art of stonemasonry. They empower professionals to push the boundaries of creativity while maintaining the highest standards of quality and safety. As we continue to innovate within this field, the future looks bright for those who rely on these powerful tools to bring their visions to life.

Request for Quotation

报错: 未找到这个表单