The Releated Products of Stone Saw Table

Stone Saw Table

Table of Contents

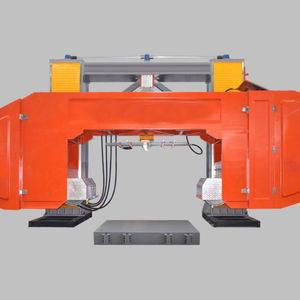

Understanding the Stone Saw Table: A Precision Tool for Cutting Stone

In the world of stone fabrication, precision and efficiency are paramount. The stone saw table has emerged as an indispensable tool for achieving these goals. Whether you’re working with granite, marble, or quartz, a reliable stone saw table can make all the difference in your workflow and final product quality. This article delves into the intricacies of stone saw tables, their components, benefits, and how to choose the right one for your needs.

Choosing the Right Stone Saw Table for Your Needs

Selecting the appropriate stone saw table depends on several factors, including the types of materials you work with, the volume of projects you handle, and your budget. For instance, if you primarily deal with thick slabs of granite, you might require a heavy-duty model with a powerful motor and robust construction. On the other hand, for smaller operations focusing on detailed work like countertop edges, a more compact and maneuverable stone saw table could be ideal.

Key Components of a Stone Saw Table

Understanding the key components of a stone saw table is crucial for maximizing its performance and longevity. Typically, these components include:

– Blade: The blade is the heart of any stone saw table. It’s responsible for cutting through the stone. High-quality blades are made from diamond segments, which are durable and effective against abrasive materials.

– Table: The flat surface where the stone is placed for cutting. It should be sturdy and level to ensure accurate cuts.

– Water System: An essential part of the stone saw table, the water system cools the blade and reduces dust during operation.

– Motor: Provides the power necessary to drive the blade through tough materials. More demanding applications require stronger motors.

Maintaining Your Stone Saw Table

Regular maintenance is vital for keeping your stone saw table in top condition. This includes cleaning the machine after each use, checking for wear and tear on parts such as belts and bearings, and replacing the blade when it becomes dull. Keeping the water system clean and free from debris also ensures optimal performance.

Safety Considerations When Using a Stone Saw Table

Safety should always come first when operating a stone saw table. Proper training on how to use the equipment correctly is essential. Additionally, wearing personal protective equipment (PPE) like safety glasses, gloves, and hearing protection is mandatory. Ensure that the stone saw table is equipped with safety features like blade guards and emergency stop buttons.

Benefits of Using a Stone Saw Table

The benefits of using a stone saw table extend beyond just making precise cuts. These machines improve productivity by allowing faster processing times compared to manual methods. They also reduce material waste, leading to cost savings over time. Furthermore, the consistent quality of cuts enhances the overall aesthetic appeal of finished products, contributing to customer satisfaction.

Advanced Features in Modern Stone Saw Tables

As technology advances, so do the capabilities of stone saw tables. Modern models often come equipped with digital readouts for precise measurements, adjustable cutting angles for versatility, and automatic feed systems for increased efficiency. These features not only make the cutting process smoother but also open up possibilities for more complex designs and patterns.

By considering these aspects, you can better understand what makes a stone saw table an essential piece of equipment for any serious stone fabricator. Whether upgrading an existing setup or starting anew, investing in a high-quality stone saw table will undoubtedly pay dividends in terms of improved efficiency and enhanced project outcomes.

Request for Quotation

报错: 未找到这个表单