The Releated Products of Stone Cutting Wire Saw

Stone Cutting Wire Saw

Table of Contents

Stone Cutting Wire Saw: Precision and Power in Modern Masonry

In the realm of stone cutting, precision and efficiency are paramount. Among the many tools used for cutting through hard materials like granite, marble, and concrete, the stone cutting wire saw stands out as a versatile and powerful solution. This article explores the technology behind these innovative machines, their applications, and the benefits they bring to the construction industry.

The Basics of Stone Cutting Wire Saws

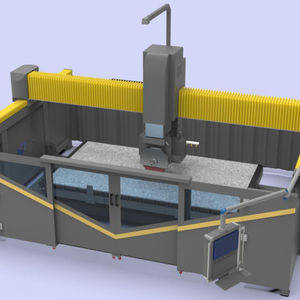

A stone cutting wire saw consists of a looped wire embedded with diamond grains that rotate around pulleys driven by a motor. The wire’s continuous motion allows it to slice through dense materials with minimal effort. Unlike traditional blade saws, which can struggle with uneven surfaces or tight spaces, stone cutting wire saws offer unparalleled flexibility and control.

Advantages of Using Stone Cutting Wire Saws

When it comes to cutting stone, using a stone cutting wire saw offers several advantages over conventional methods. These include:

– Precision Cutting: The ability to make clean, straight cuts with minimal vibration makes stone cutting wire saws ideal for detailed work.

– Reduced Dust Production: By utilizing water during the cutting process, stone cutting wire saws help suppress dust, creating a safer working environment.

– Cost-Effectiveness: Though initially more expensive, the longer lifespan and reduced need for maintenance mean that stone cutting wire saws can be cost-effective over time.

Applications of Stone Cutting Wire Saws

From construction sites to quarries, the applications of stone cutting wire saws are diverse and essential. They are commonly used for:

– Quarrying: Extracting large blocks of stone from quarries efficiently.

– Demolition: Removing sections of concrete structures without damaging surrounding areas.

– Rescue Operations: In emergency scenarios where quick and precise cutting is necessary.

How Stone Cutting Wire Saws Work

Understanding how a stone cutting wire saw operates is crucial for maximizing its potential. Essentially, the saw uses a thin, circular wire studded with industrial diamonds that act as cutting edges. When this wire is stretched between two or more pulleys and rotated at high speeds, it can cut through almost any material. The key components of a stone cutting wire saw include:

– Diamond-Coated Wire: Provides the cutting action.

– Pulleys: Guide the wire along its path.

– Motor: Drives the system, providing the power needed for cutting.

Maintenance and Care of Stone Cutting Wire Saws

To ensure optimal performance and longevity, proper maintenance of your stone cutting wire saw is vital. Regular checks should be made on:

– Wire Tension: Keeping the wire taut ensures efficient cutting.

– Lubrication: Applying lubricants reduces friction and wear on moving parts.

– Cleanliness: Removing debris keeps the machine running smoothly.

Future Innovations in Stone Cutting Wire Saws

As technology advances, so too does the design and functionality of stone cutting wire saws. Emerging trends include:

– Automation: Increasingly sophisticated controls allow for more precise cuts with less manual intervention.

– Eco-Friendly Designs: New models focus on reducing environmental impact through improved energy efficiency and lower emissions.

– Durability Enhancements: Advanced materials are being tested to extend the life of both the wire and supporting hardware.

By embracing these advancements, manufacturers continue to push the boundaries of what’s possible with stone cutting wire saws, ensuring they remain indispensable tools for professionals worldwide.

Request for Quotation

报错: 未找到这个表单