The Releated Products of Stone Cutting Machinery

Stone Cutting Machinery

Table of Contents

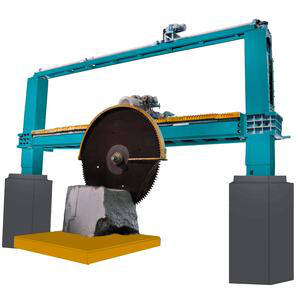

Stone Cutting Machinery: Precision, Power, and Performance

In the dynamic world of construction and architecture, stone cutting machinery plays a pivotal role. These machines are designed to meet the rigorous demands of cutting, shaping, and finishing various types of stones, including granite, marble, and limestone. With advancements in technology, modern stone cutting equipment offers unparalleled precision, efficiency, and safety. This article explores the key aspects of stone cutting machinery, highlighting its importance and innovations.

Stone Cutting Machinery: Enhancing Efficiency

Efficiency is critical in the stone cutting industry, where time and accuracy can significantly impact project outcomes. Stone cutting machinery equipped with advanced features such as CNC (Computer Numerical Control) systems has revolutionized the way stones are processed. CNC machines allow for precise cuts and intricate designs, reducing waste and improving productivity. Additionally, these machines can handle large volumes of work without compromising on quality, making them indispensable in high-volume operations.

Stone Cutting Machinery: Ensuring Safety Standards

Safety is another crucial aspect of using stone cutting machinery. Given the nature of materials being worked on—hard, heavy stones—there’s always a risk of accidents if proper precautions aren’t taken. Manufacturers of stone cutting equipment have responded by incorporating numerous safety features into their designs. These include emergency stop buttons, protective guards around moving parts, and dust extraction systems that minimize health hazards associated with airborne particles.

Stone Cutting Machinery: Driving Technological Advancements

Technological advancements continue to shape the future of stone cutting machinery. Innovations like laser cutting, water jet technology, and robotic arms are becoming more prevalent, offering even greater precision and versatility. Laser cutting, for instance, allows for extremely accurate cuts with minimal material deformation, ideal for creating detailed sculptures or complex architectural elements. Water jet technology uses a high-pressure stream of water mixed with abrasive substances to cut through stone, providing a clean edge and reducing thermal damage.

Stone Cutting Machinery: Customization Options

The demand for unique designs and personalized products has led to an increased focus on customization capabilities within stone cutting machinery. Modern machines offer a wide range of tools and attachments that can be easily swapped out depending on the job requirements. This flexibility enables operators to switch between different tasks quickly, from rough cutting to fine polishing, ensuring that each piece meets specific client needs.

Stone Cutting Machinery: Sustainable Practices

Environmental sustainability is increasingly becoming a priority in the manufacturing sector, including stone cutting industries. Newer models of stone cutting machinery are designed with energy efficiency in mind, utilizing motors that consume less power while maintaining performance levels. Moreover, efforts are being made to recycle water used in the cutting process and reduce noise pollution, contributing to greener operations.

Stone Cutting Machinery: Training and Support

To fully leverage the capabilities of advanced stone cutting machinery, proper training and ongoing support are essential. Many manufacturers provide comprehensive training programs that cover everything from basic operation to troubleshooting and maintenance. This ensures that users not only know how to operate the machines effectively but also understand how to maintain them, extending their lifespan and maximizing return on investment.

In conclusion, stone cutting machinery represents a significant investment for businesses involved in stonework. By focusing on efficiency, safety, technological innovation, customization, sustainability, and user training, these machines continue to drive growth and excellence in the industry. Whether you’re a seasoned professional or just starting out, understanding the key features and benefits of stone cutting machinery is vital for success in today’s competitive market.

Request for Quotation

报错: 未找到这个表单