The Releated Products of Stone Concrete Saw

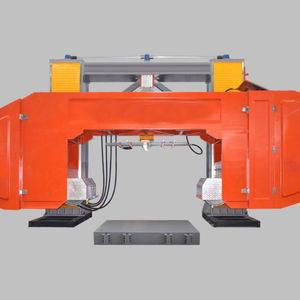

Stone Concrete Saw

Understanding the Versatility of Stone Concrete Saws

In the realm of construction and masonry work, precision and efficiency are paramount. This is where stone concrete saws come into play, offering unparalleled capabilities for cutting through some of the toughest materials. Whether you’re dealing with reinforced concrete, asphalt, or even natural stone, these tools are designed to meet the demands of both small-scale projects and large construction sites. But what makes them so effective? Let’s delve deeper into the world of stone concrete saws, exploring their features, applications, and benefits.

Key Features of Stone Concrete Saws

When it comes to stone concrete saws, several key features stand out, making them indispensable tools for professionals. First and foremost, the blade design plays a critical role. Typically made from diamond segments, these blades can cut through dense materials like concrete with ease. Additionally, water cooling systems help maintain optimal operating temperatures, extending the life of the blade while reducing dust and debris.

Applications of Stone Concrete Saws in Construction

The application scope of stone concrete saws is broad, covering everything from road construction to building renovations. For instance, they are ideal for creating expansion joints in pavements, cutting doorways in existing walls, and removing damaged sections of concrete slabs. Their ability to make precise cuts minimizes material waste and ensures a clean finish, which is crucial for both aesthetic and structural integrity.

Choosing the Right Stone Concrete Saw for Your Project

Selecting the appropriate stone concrete saw depends on factors such as the size of the project, the type of material being cut, and your budget constraints. For larger projects requiring extensive cutting, a walk-behind model might be more suitable due to its power and stability. On the other hand, handheld models offer greater maneuverability and are perfect for smaller jobs or tight spaces. Consider also whether you need a wet or dry cutting system based on local regulations and safety requirements.

Maintenance Tips for Stone Concrete Saws

Like any piece of heavy-duty machinery, stone concrete saws require regular maintenance to function optimally. Keeping the blade clean and free from debris is essential. Regularly inspecting the water supply system ensures that it continues to effectively cool the blade during operation. Additionally, replacing worn parts promptly can prevent more serious damage and costly repairs down the line.

Safety Precautions When Using Stone Concrete Saws

Safety should always be a top priority when operating stone concrete saws. Proper personal protective equipment (PPE), including eye protection, hearing protection, and dust masks, is a must. Familiarize yourself with the manufacturer’s instructions regarding safe operating procedures. Keep bystanders at a safe distance, and never operate the saw without the necessary guards in place.

Advancements in Technology for Stone Concrete Saws

As technology evolves, so do the capabilities of stone concrete saws. Modern designs incorporate features such as electric start engines, improved exhaust systems, and more efficient blade configurations. These advancements not only enhance performance but also contribute to reduced noise levels and better environmental compliance. Keeping abreast of these innovations can significantly impact productivity and sustainability efforts within construction projects.

Stone concrete saws continue to be vital tools in the construction industry, offering a combination of power, precision, and versatility that few other pieces of equipment can match. By understanding their key features, applications, and proper usage, professionals can leverage these machines to achieve outstanding results efficiently and safely.

Request for Quotation

报错: 未找到这个表单