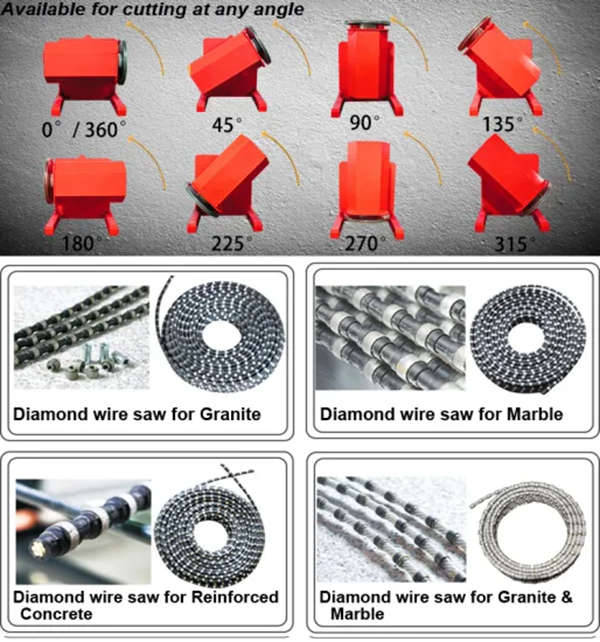

The Releated Products of Small Precision Diamond Wire Saw Slicing Machine

Small Precision Diamond Wire Saw Slicing Machine

Small Precision Diamond Wire Saw Slicing Machine: Precision Engineering for Advanced Applications

Precision Engineering of Small Diamond Wire Saw Slicing Machines

In the realm of advanced manufacturing and material processing, the need for precision and accuracy has never been greater. Small precision diamond wire saw slicing machines have emerged as indispensable tools in industries ranging from semiconductor fabrication to aerospace engineering. These machines leverage the unparalleled cutting capabilities of diamond wires to achieve clean, precise cuts on a variety of materials, including silicon wafers, ceramics, and other hard-to-cut materials.

The design of these machines is centered around minimizing vibration and maximizing stability, which are critical for achieving the high levels of precision required in these applications. With a focus on ergonomic design and user-friendly interfaces, operators can achieve optimal performance with minimal training, enhancing productivity and reducing downtime.

Benefits of Using Small Precision Diamond Wire Saw Slicing Machines

Enhanced Cutting Accuracy

One of the primary advantages of using small precision diamond wire saw slicing machines is their ability to achieve extremely accurate cuts. The diamond wire, known for its hardness and durability, allows for consistent cutting performance across a wide range of materials. This consistency is crucial in applications where even the slightest deviation can lead to significant defects or scrap.

Versatility in Material Handling

Small precision diamond wire saw slicing machines are not limited to a single type of material. They can effectively handle everything from brittle materials like glass and ceramics to more resilient materials such as metals and composites. This versatility makes them a valuable asset in research and development environments where experimentation with different materials is common.

Reduced Material Waste

By offering precise control over the cutting process, these machines minimize material waste, which is particularly important when working with expensive materials. The ability to make thinner kerfs (cuts) also contributes to higher yields, making the overall production process more cost-effective.

Key Features of Small Precision Diamond Wire Saw Slicing Machines

High-Speed Cutting Capability

Equipped with powerful motors and optimized drive systems, small precision diamond wire saw slicing machines can achieve high-speed cutting without compromising on accuracy. This feature is essential for maintaining high throughput rates in industrial settings, ensuring that production targets are met efficiently.

Automated Tension Control

To ensure consistent cutting performance, these machines often incorporate automated tension control mechanisms for the diamond wire. This system adjusts the tension based on the material being cut and the cutting speed, preventing slippage or breakage of the wire, which could otherwise lead to costly downtime and material damage.

User-Friendly Interface

Modern small precision diamond wire saw slicing machines come with intuitive control panels and software interfaces that simplify operation. Real-time monitoring and adjustment options allow operators to fine-tune the cutting parameters according to specific requirements, enhancing both precision and efficiency.

Applications of Small Precision Diamond Wire Saw Slicing Machines

From the delicate slicing of semiconductor wafers to the robust cutting of aerospace components, small precision diamond wire saw slicing machines find extensive use across various sectors. Their ability to deliver consistent results while handling diverse materials makes them a preferred choice for manufacturers seeking to enhance their product quality and operational efficiency.

In conclusion, the integration of advanced technologies and ergonomic design principles in small precision diamond wire saw slicing machines underscores their importance in modern manufacturing processes. As industries continue to push the boundaries of material science and precision engineering, these machines will undoubtedly play a pivotal role in driving innovation and excellence.

Request for Quotation

报错: 未找到这个表单