The Releated Products of Slab Master Diamond Wire Saw

Slab Master Diamond Wire Saw

Table of Contents

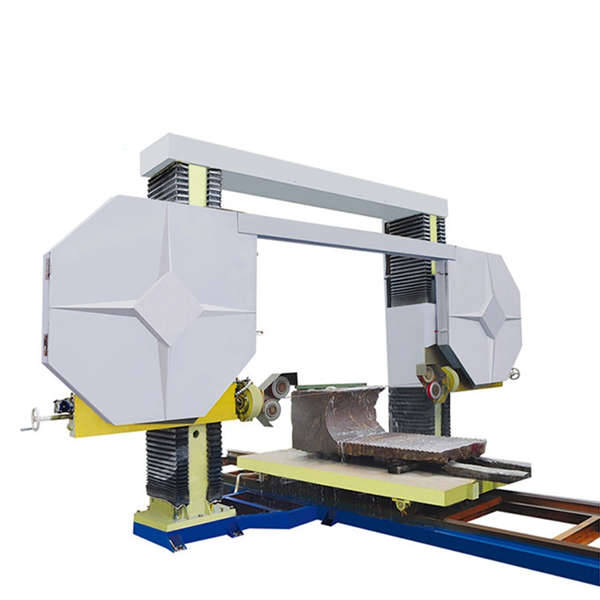

The Precision and Power of the Slab Master Diamond Wire Saw

Slab Master Diamond Wire Saw: Cutting Through Concrete with Ease

When it comes to cutting through thick concrete slabs, precision and power are paramount. The Slab Master Diamond Wire Saw is a game-changer in the construction industry, offering unparalleled performance and efficiency. This specialized tool is designed for heavy-duty applications where traditional methods fall short. Its robust construction and advanced features make it a must-have for contractors tackling large-scale projects.

Advantages of Using the Slab Master Diamond Wire Saw

The Slab Master Diamond Wire Saw stands out due to its numerous advantages over conventional cutting methods. One key benefit is its ability to cut through reinforced concrete and other hard materials with minimal effort. The saw’s diamond-impregnated wire ensures clean, straight cuts every time, reducing waste and saving time on site. Additionally, its low-vibration design makes it comfortable to operate, enhancing user safety and productivity.

Applications of the Slab Master Diamond Wire Saw

From bridge demolition to floor cutting, the Slab Master Diamond Wire Saw has a wide range of applications in the construction sector. Its versatility allows it to tackle various jobs with ease, making it a valuable asset for any contractor’s toolbox. Whether you’re working on residential renovations or commercial building sites, this powerful tool can handle the task efficiently and effectively.

Features of the Slab Master Diamond Wire Saw

To understand why the Slab Master Diamond Wire Saw is so effective, one must consider its key features. The saw is equipped with a high-torque motor that delivers consistent power throughout the cutting process. Its adjustable guide system ensures precise control, while the interchangeable wire configuration allows users to adapt to different material thicknesses and hardness levels. These features combine to provide a cutting solution that is both versatile and reliable.

Maintenance of the Slab Master Diamond Wire Saw

Like all heavy-duty machinery, the Slab Master Diamond Wire Saw requires regular maintenance to ensure optimal performance. Routine checks on the wire tension, guide blocks, and lubrication systems are essential for prolonging the life of the equipment. Proper cleaning after each use is also important to prevent debris buildup that could affect future operations. By following these maintenance guidelines, operators can keep their Slab Master Diamond Wire Saw running smoothly and avoid costly downtime.

Buying Guide for the Slab Master Diamond Wire Saw

Choosing the right Slab Master Diamond Wire Saw involves considering several factors such as project size, frequency of use, and budget constraints. For occasional users, a mid-range model might suffice; however, professionals handling multiple projects simultaneously may benefit more from a top-of-the-line version. Regardless of the specific needs, investing in a quality Slab Master Diamond Wire Saw will undoubtedly pay off in terms of productivity and job satisfaction.

Conclusion on the Slab Master Diamond Wire Saw

In conclusion, the Slab Master Diamond Wire Saw represents a significant advancement in concrete cutting technology. Its combination of power, precision, and durability makes it an indispensable tool for modern construction projects. As demand continues to grow for efficient and reliable cutting solutions, the Slab Master Diamond Wire Saw remains at the forefront, setting new standards for performance and reliability. Whether you’re a seasoned professional or just starting out, this innovative piece of equipment is sure to meet your cutting needs and exceed your expectations.

Request for Quotation

报错: 未找到这个表单