The Releated Products of Sawing Diamond Wire Rope

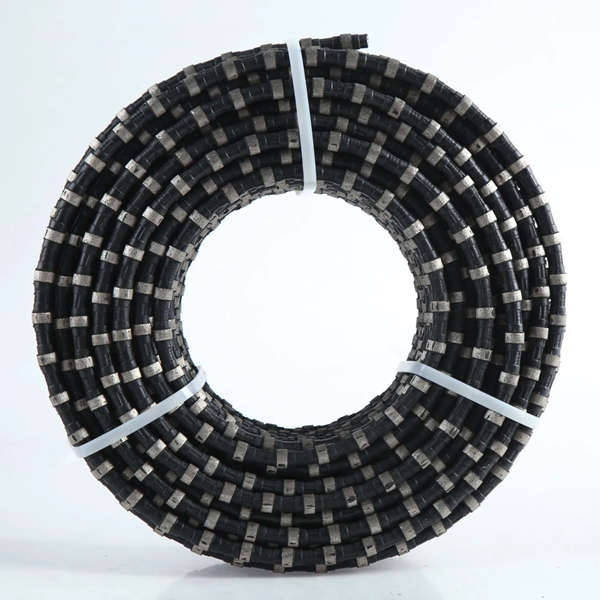

Sawing Diamond Wire Rope

Table of Contents

Understanding the Basics of Sawing Diamond Wire Rope

Sawing diamond wire rope is a specialized process used extensively in industries such as mining, construction, and manufacturing. This technique involves using a thin, flexible wire embedded with diamond particles to cut through hard materials like concrete, stone, and metal. The efficiency and precision of diamond wire sawing make it indispensable for a variety of applications where traditional cutting methods fall short.

Benefits of Using Diamond Wire Rope for Sawing

When considering the advantages of sawing diamond wire rope, several key points emerge. Firstly, this method offers unparalleled precision, allowing for clean cuts with minimal material loss. Additionally, the ability to cut in confined spaces or around obstacles without vibration makes it ideal for complex projects. Another significant benefit is its speed; diamond wire can slice through thick sections much faster than conventional saws, reducing overall project timelines and costs.

Techniques in Sawing Diamond Wire Rope

To achieve optimal results when sawing diamond wire rope, it’s crucial to employ proper techniques. Preparation is vital; ensuring the work area is clear and the material to be cut is stable prevents accidents and ensures accuracy. Tensioning the wire correctly is also essential; too loose, and the wire may slip or break; too tight, and it could cause unnecessary wear on the machinery. Lastly, controlling the feed rate and applying consistent pressure helps maintain a steady, controlled cut.

Applications of Sawing Diamond Wire Rope

The versatility of sawing diamond wire rope means it has found applications across multiple sectors. In construction, it’s used for demolishing structures, cutting openings in existing walls, and dividing large slabs of concrete. For mining operations, diamond wire saws enable precise extraction of valuable minerals from rock formations. Manufacturers appreciate its capability to produce intricate shapes from metals and other tough materials with high accuracy and repeatability.

Maintenance of Diamond Wire Ropes Used in Sawing

Proper maintenance extends the lifespan of diamond wire ropes significantly. Regular inspection for signs of wear such as fraying or loss of diamond grit ensures safety and performance. Cleaning the wire after each use removes debris that could interfere with future cuts. Lubricating moving parts reduces friction and heat buildup during operation. When stored properly away from moisture and extreme temperatures, diamond wire ropes retain their strength and cutting efficiency over extended periods.

Safety Considerations When Sawing With Diamond Wire Rope

Safety must always come first when working with diamond wire saws. Operators need comprehensive training on how to handle the equipment safely and understand potential hazards associated with the process. Protective gear including goggles, gloves, and hearing protection should be worn at all times. Ensuring the work environment complies with relevant health and safety regulations minimizes risks to personnel and property damage.

Future Innovations in Sawing Diamond Wire Rope Technology

Advancements in technology continue to enhance the capabilities of sawing diamond wire rope. Research into new materials for the wire core and abrasive coatings promises increased durability and cutting power. Integration of automation and robotics into the sawing process aims to improve efficiency further while reducing labor requirements. As these innovations evolve, we can expect even more precise and efficient cutting solutions in the near future.

Request for Quotation

报错: 未找到这个表单