The Releated Products of Sawing And Polishing Stones

Sawing And Polishing Stones

Table of Contents

The Art of Sawing and Polishing Stones: Transforming Raw Materials into Masterpieces

Sawing and polishing stones is not merely a process—it’s an art form that transforms raw, often unremarkable materials into breathtaking pieces of beauty. This practice has been around for centuries, evolving alongside human civilization and technology. Today, it remains a vital industry, blending traditional techniques with modern machinery to produce stunning results. Let’s delve deeper into the world of sawing and polishing stones, exploring its intricacies and significance.

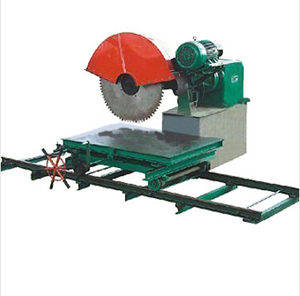

Sawing and Polishing Stones: The Initial Cut

The first step in this transformation is sawing and polishing stones, where rough stones are cut into more manageable sizes and shapes. Specialized saws equipped with diamond blades are used due to their ability to cut through even the hardest materials. The precision required during this stage sets the foundation for all subsequent steps. Water is continuously sprayed onto the stone and blade to cool them and prevent overheating, which could damage the material.

Selecting Tools for Sawing and Polishing Stones

Choosing the right tools for sawing and polishing stones is crucial. For cutting, diamond blades come in various sizes and configurations, tailored to different hardness levels of stones. Abrasive pads, ranging from coarse to fine grits, are essential for achieving a smooth finish. Each tool plays a critical role in bringing out the natural beauty of the stone while ensuring durability and longevity of the finished product.

Techniques Involved in Sawing and Polishing Stones

Different techniques are employed when sawing and polishing stones, depending on the desired outcome and characteristics of the stone itself. For example, softer stones might require gentler handling compared to harder ones like granite or quartzite. Experienced craftsmen use their skills to determine the best approach, ensuring minimal waste and maximum aesthetic appeal. Modern technologies such as CNC machines have also revolutionized these processes by allowing for intricate designs and consistent quality.

Safety Measures During Sawing and Polishing Stones

Safety is paramount when sawing and polishing stones, especially considering the dust and noise generated during operations. Workers must wear protective gear including goggles, masks, and ear protection. Ventilation systems help manage airborne particles, reducing health risks associated with prolonged exposure. Regular maintenance of equipment is necessary to prevent accidents and ensure optimal performance.

Environmental Impact of Sawing and Polishing Stones

While the process of sawing and polishing stones yields beautiful results, it’s important to consider its environmental impact. Efforts are being made to minimize water usage and properly dispose of waste products. Some companies are exploring sustainable sourcing practices and recycling programs to reduce their ecological footprint. Innovations in machinery design are also contributing towards greener manufacturing processes.

Future Trends in Sawing and Polishing Stones

As technology advances, so does the field of sawing and polishing stones. Automation and robotics are increasingly being integrated into production lines, enhancing efficiency and accuracy. There’s also a growing trend towards customization, allowing customers to have a more personal connection with their stone products. Additionally, research into new materials and methods continues, promising exciting developments in the years to come.

By understanding the complexities involved in sawing and polishing stones, one can appreciate not only the final product but also the skill and dedication behind its creation. Whether used for functional purposes or artistic expression, these stones serve as timeless symbols of craftsmanship and innovation.

Request for Quotation

报错: 未找到这个表单