The Releated Products of Saw To Cut Ceramic Glass

Saw To Cut Ceramic Glass

Table of Contents

Selecting the Right Saw to Cut Ceramic Glass

When it comes to cutting ceramic glass, precision and accuracy are paramount. Ceramic glass is a durable material used extensively in kitchen countertops, table tops, and even stovetops due to its heat-resistant properties. However, working with this material requires specialized tools to achieve clean, smooth cuts without chipping or cracking. A saw to cut ceramic glass is a must-have for any DIY enthusiast or professional looking to work with this versatile material.

Choosing the Best Saw to Cut Ceramic Glass

The first step in ensuring a successful project involving ceramic glass is selecting the right saw. There are several types of saws on the market designed specifically for cutting through hard materials like ceramic glass. A wet tile saw, for example, uses water to cool the blade and reduce dust while cutting. This type of saw to cut ceramic glass provides a more controlled and cleaner cut compared to dry cutting methods.

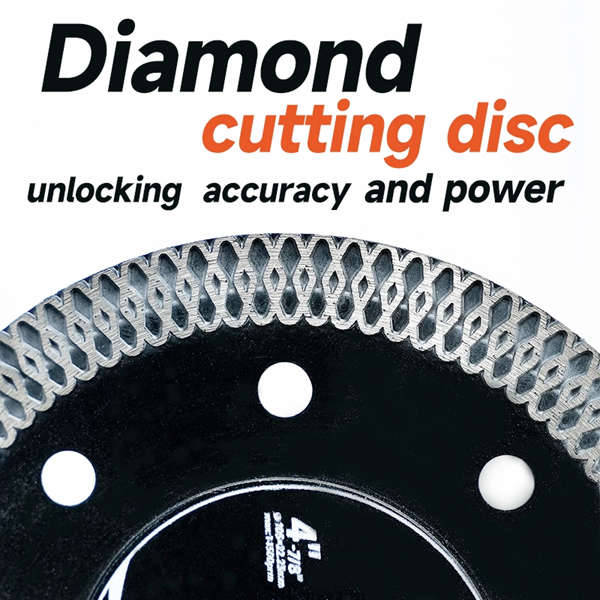

Another option is a diamond blade saw, which can be either wet or dry. Diamond blades are coated with industrial diamonds that grind away at the surface of the ceramic glass, making them highly effective for this purpose. When choosing a saw to cut ceramic glass, consider factors such as blade size, power, and whether it’s a wet or dry system.

Preparing Your Workspace for Cutting Ceramic Glass

Before you begin using your saw to cut ceramic glass, it’s crucial to set up your workspace properly. Ensure that your work area is well-lit and free from clutter. Place the ceramic glass piece securely on a stable platform or table that can support its weight. Using clamps or a vice to hold the material in place will prevent it from moving during the cutting process, ensuring straight lines and reducing the risk of injury.

Additionally, if you’re using a wet saw to cut ceramic glass, make sure you have access to a water source and a way to dispose of wastewater safely. Always wear protective gear, including safety glasses, gloves, and a dust mask, when working with ceramic glass.

Techniques for Cutting Ceramic Glass Smoothly

Using a saw to cut ceramic glass effectively requires some skill and practice. Start by marking the glass where you want to make the cut using a marker or chalk. This guideline helps keep the saw blade aligned throughout the cut. For best results, apply steady pressure and move the blade slowly along the marked line.

It’s also important to maintain a consistent speed when operating the saw to cut ceramic glass. Sudden movements or applying too much force can cause the material to crack or chip. Take breaks if necessary to avoid overheating the blade, especially if you’re working on a large project.

Maintaining Your Saw to Cut Ceramic Glass

Proper maintenance of your saw to cut ceramic glass extends its lifespan and ensures optimal performance. After each use, clean the saw thoroughly to remove any debris or residue. For wet saws, rinse the blade and other parts that came into contact with water. Dry all components completely to prevent rust.

Regularly inspect the blade for wear and tear. Replace the blade if you notice any damage or dullness, as this can affect the quality of your cuts. Lubricate moving parts according to the manufacturer’s instructions to keep the saw to cut ceramic glass running smoothly.

Troubleshooting Common Issues When Cutting Ceramic Glass

Even with the right saw to cut ceramic glass and proper technique, you may encounter issues during the cutting process. Cracking or chipping along the cut line often indicates that the blade isn’t being guided correctly or that the material wasn’t secured tightly enough. Adjust your grip on the saw and ensure the ceramic glass is firmly held in place before attempting another cut.

If the saw to cut ceramic glass seems to be struggling or overheating, stop immediately and check the blade. It might need sharpening or replacement. Overheating can also occur if you’re cutting too quickly; slow down and allow the blade to cool periodically.

By following these guidelines and investing in a high-quality saw to cut ceramic glass, you’ll be well-equipped to handle any project involving this challenging material. Whether you’re a seasoned professional or a DIY enthusiast, the right tools and techniques can make all the difference in achieving precise, professional-looking results.

Request for Quotation

报错: 未找到这个表单