The Releated Products of Rope Saw Concrete

Rope Saw Concrete

Table of Contents

Understanding the Power of Rope Saw Concrete

In the realm of construction and demolition, precision and efficiency are paramount. One innovative method that has revolutionized these industries is rope saw concrete cutting. This technique employs diamond-impregnated cables to slice through dense materials like reinforced concrete, stone, and masonry with remarkable accuracy. By exploring the principles behind rope saw concrete technology, its applications, and benefits, we can better understand how this method is shaping modern construction practices.

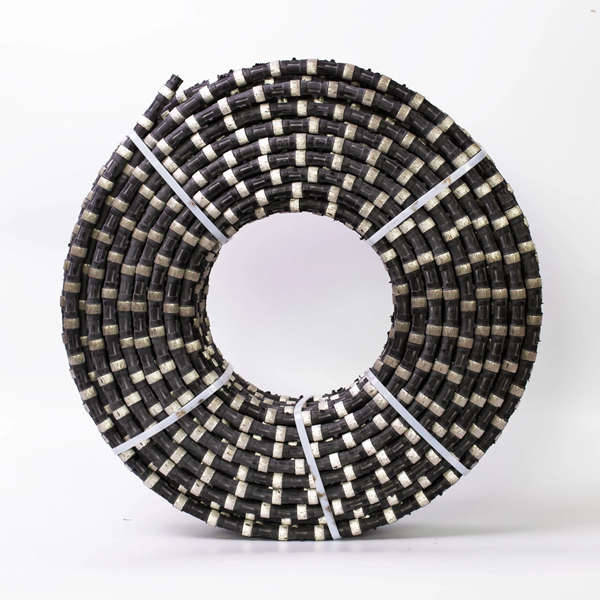

The Basics of Rope Saw Concrete Cutting

Rope saw concrete cutting involves using a thin, flexible cable embedded with industrial diamonds. These cables are driven by high-torque motors, creating a fast and controlled cutting action. Unlike traditional methods such as wire sawing or wall sawing, rope saw concrete offers unparalleled flexibility and reach. It can navigate tight spaces and cut deep into structures without compromising stability or surrounding areas.

Advantages of Using Rope Saw Concrete Techniques

When it comes to cutting large volumes of concrete, speed and safety are critical factors. Rope saw concrete technology excels in both areas. It reduces noise and vibration compared to conventional cutting tools, making it ideal for sensitive environments. Additionally, the system’s modular design allows for easy setup and teardown, minimizing downtime on job sites. This adaptability makes rope saw concrete a preferred choice for contractors tackling complex projects.

Applications of Rope Saw Concrete in Construction

From bridge demolition to foundation removal, the applications of rope saw concrete are vast. Its ability to cut precise lines and shapes enables architects and engineers to execute designs with greater creativity and precision. Whether it’s carving out openings for new windows or removing sections of a building floor by floor, rope saw concrete provides a solution that is both effective and cost-efficient.

Environmental Impact of Rope Saw Concrete Methods

Sustainability is increasingly becoming a priority in construction projects. Rope saw concrete contributes positively to this trend by reducing waste and minimizing the use of harmful chemicals typically associated with other cutting processes. The clean cuts produced by rope saws also mean less material needs to be removed post-cutting, further lowering environmental impact.

Training and Safety Measures for Rope Saw Concrete Operators

Given the power and precision required when working with rope saw concrete, proper training and adherence to safety protocols are essential. Operators must undergo rigorous instruction to master the nuances of operating these machines safely and efficiently. Regular maintenance checks ensure that the equipment remains in optimal condition, reducing the risk of accidents during operation.

Future Innovations in Rope Saw Concrete Technology

As technology continues to evolve, so too does the potential for rope saw concrete advancements. Research into stronger, more durable diamond compounds could lead to even faster cutting speeds and longer-lasting blades. Integration with artificial intelligence and robotics might automate certain aspects of the cutting process, improving accuracy and reducing human labor requirements. These developments promise to make rope saw concrete an even more indispensable tool in the construction industry’s toolbox.

By embracing the capabilities of rope saw concrete, professionals in the field stand to gain significant advantages in terms of productivity, safety, and environmental responsibility. As this technology matures, it will undoubtedly play a pivotal role in shaping the future of construction and demolition practices worldwide.

Request for Quotation

报错: 未找到这个表单