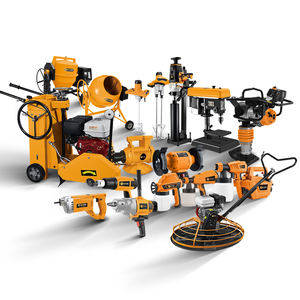

The Releated Products of Roof Tile Cutter

Roof Tile Cutter

Table of Contents

Roof Tile Cutter: Precision Tool for Seamless Roofing Projects

Roof tile cutters are indispensable tools in the roofing industry, providing precise cuts for a wide range of roofing materials. Whether you’re working on a small repair job or a large-scale construction project, having the right roof tile cutter can make all the difference. This article explores the essential features, types, and benefits of using a roof tile cutter, as well as tips for selecting the best one for your needs.

Types of Roof Tile Cutters

When it comes to choosing a roof tile cutter, there are several options available, each suited for different tasks and environments. Manual roof tile cutters are ideal for small projects or occasional use due to their simplicity and affordability. These tools typically consist of a guide rail, a scoring wheel, and a breaking mechanism. For more demanding applications, electric roof tile cutters offer increased power and efficiency. They can handle thicker tiles and continuous cutting without the physical strain associated with manual models.

Benefits of Using a Roof Tile Cutter

Using a roof tile cutter offers numerous advantages over traditional cutting methods. One of the most significant benefits is the precision it provides. A good roof tile cutter ensures clean, straight cuts every time, reducing waste and improving the overall quality of the finished roof. Additionally, these tools enhance safety by minimizing the risk of chipping or cracking tiles during the cutting process. This is particularly important when working with expensive or delicate materials.

Features to Consider When Choosing a Roof Tile Cutter

Selecting the right roof tile cutter depends on several key factors, including the type of tiles you’ll be cutting, the frequency of use, and your budget. For frequent, heavy-duty use, look for a model with a robust motor and durable construction. Adjustable cutting guides and depth settings are also crucial for versatility and accuracy. If portability is a concern, consider lightweight designs that are easy to transport between job sites. Lastly, ensure that the roof tile cutter you choose comes with adequate safety features such as guards and emergency stop buttons.

Maintenance Tips for Your Roof Tile Cutter

To keep your roof tile cutter performing at its best, regular maintenance is essential. Start by cleaning the tool after each use to remove any debris or residue. Check the blades periodically for wear and replace them as needed to maintain cutting efficiency. Lubricating moving parts will help prevent rust and ensure smooth operation. Finally, store your roof tile cutter in a dry, secure location to protect it from damage and unauthorized use.

How to Use a Roof Tile Cutter Safely and Effectively

Proper use of a roof tile cutter not only enhances productivity but also ensures user safety. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Read the manufacturer’s instructions thoroughly before operating the tool for the first time. When making cuts, apply steady pressure and follow the guide lines carefully to achieve accurate results. Never force the blade through the material; allow the roof tile cutter to do the work at its own pace.

Common Issues and Solutions for Roof Tile Cutters

Like any piece of equipment, roof tile cutters may encounter issues over time. Common problems include dull blades, misaligned guides, and malfunctioning motors. Addressing these issues promptly can extend the life of your tool and maintain optimal performance. For instance, replacing a dull blade with a sharp one can significantly improve cutting efficiency. Regular alignment checks and adjustments will ensure consistent, accurate cuts. In case of electrical failures, consult a professional technician for repairs.

By understanding the capabilities and limitations of roof tile cutters, professionals can maximize their efficiency and produce high-quality results on every project. Whether you’re a seasoned roofer or just starting out, investing in a reliable roof tile cutter is a decision that will pay off in terms of both time savings and superior craftsmanship.

Request for Quotation

报错: 未找到这个表单