The Releated Products of Reciprocating Diamond Wire Saw For Lapidary

Reciprocating Diamond Wire Saw For Lapidary

Table of Contents

Understanding the Reciprocating Diamond Wire Saw for Lapidary

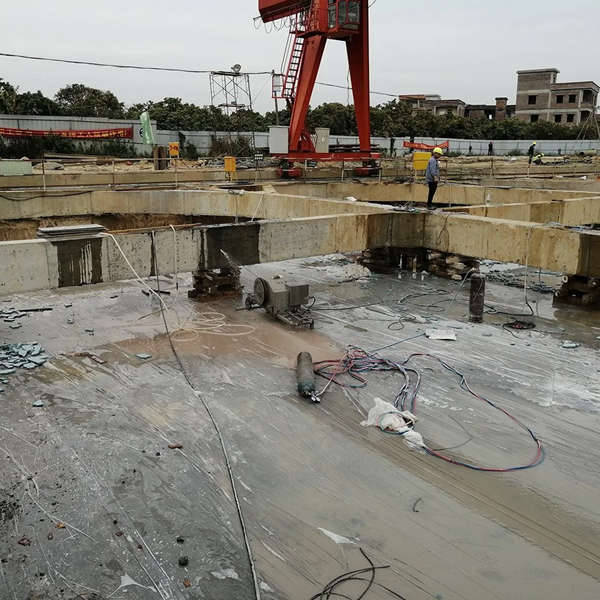

In the intricate world of lapidary, precision and efficiency are paramount. One tool that has revolutionized stone cutting and shaping is the reciprocating diamond wire saw. This advanced machinery offers unparalleled accuracy and speed, making it indispensable for both hobbyists and professionals alike.

Advantages of Using a Reciprocating Diamond Wire Saw For Lapidary

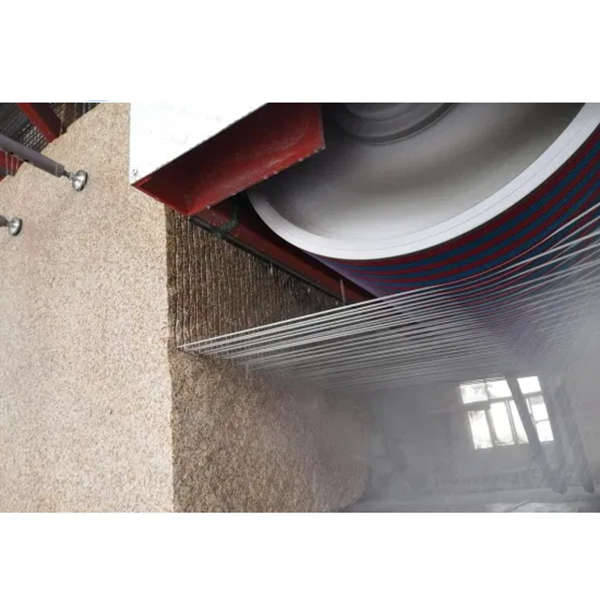

The reciprocating diamond wire saw stands out due to its unique design and operational capabilities. Unlike traditional blade saws, which can cause significant material loss and wear on the stone, this technology utilizes a thin wire embedded with industrial diamonds. This setup ensures minimal waste while providing a clean, smooth cut every time. Additionally, because the wire can be as thin as 0.6mm, users can achieve highly detailed work that would otherwise be impossible with bulkier tools.

Maintenance Tips for Your Reciprocating Diamond Wire Saw For Lapidary

To keep your reciprocating diamond wire saw functioning optimally, regular maintenance is essential. First, ensure that the wire remains properly tensioned; a loose wire not only affects performance but can also lead to premature wear. Secondly, always use the recommended lubricant, as this helps reduce friction and heat buildup during operation. Lastly, inspect the machine regularly for any signs of damage or wear, replacing parts as necessary to avoid costly repairs down the line.

Selecting the Right Reciprocating Diamond Wire Saw For Lapidary

When choosing a reciprocating diamond wire saw for lapidary purposes, several factors come into play. Consider the size and hardness of the stones you’ll be working with most frequently. For larger, harder materials like granite or quartz, a more robust model with a thicker wire might be preferable. Conversely, if your projects involve delicate gemstones, opt for a saw with finer wires capable of producing thinner cuts without damaging the material.

Techniques for Efficient Cutting with a Reciprocating Diamond Wire Saw For Lapidary

Mastering the art of using a reciprocating diamond wire saw efficiently requires practice and understanding of proper techniques. Start by marking your intended cut lines clearly on the stone. This not only guides your hand but also helps maintain consistency throughout the project. When operating the saw, apply gentle pressure and allow the machine’s momentum to do most of the work. Rushing or forcing the cut can result in jagged edges or even breakage of the stone.

Safety Precautions When Working with a Reciprocating Diamond Wire Saw For Lapidary

Safety should always be a top priority when working with any power tool, including reciprocating diamond wire saws. Always wear appropriate personal protective equipment (PPE), such as safety goggles, ear protection, and dust masks. Ensure that all guards are in place and functioning correctly before starting the machine. Additionally, never leave the saw unattended while it’s running, and make sure to unplug it when performing maintenance or changing wires.

By embracing the power and versatility of a reciprocating diamond wire saw, lapidary enthusiasts can elevate their craft to new heights. With careful selection, diligent maintenance, and adherence to best practices, these machines become invaluable assets in creating stunning works of art from nature’s most precious materials.

Request for Quotation

报错: 未找到这个表单