The Releated Products of Quarry Diamond Wire Saw Machine

Quarry Diamond Wire Saw Machine

Table of Contents

Understanding the Quarry Diamond Wire Saw Machine: Precision in Stone Extraction

In the world of stone quarrying and extraction, precision and efficiency are paramount. The introduction of the quarry diamond wire saw machine has revolutionized this industry by offering unparalleled accuracy and speed in cutting through hard materials like granite, marble, and limestone. This article explores the key features, benefits, and applications of these machines, providing insights into why they have become indispensable tools for modern quarries.

Advantages of Using a Quarry Diamond Wire Saw Machine

The quarry diamond wire saw machine stands out for several reasons, primarily due to its ability to cut large blocks of stone with minimal waste. Unlike traditional methods that often result in cracked or damaged stones, the wire saw ensures clean cuts, preserving the integrity of the material. Additionally, these machines operate with less noise and vibration compared to explosive or mechanical splitting techniques, making them environmentally friendly and safer for workers.

Innovative Design of the Quarry Diamond Wire Saw Machine

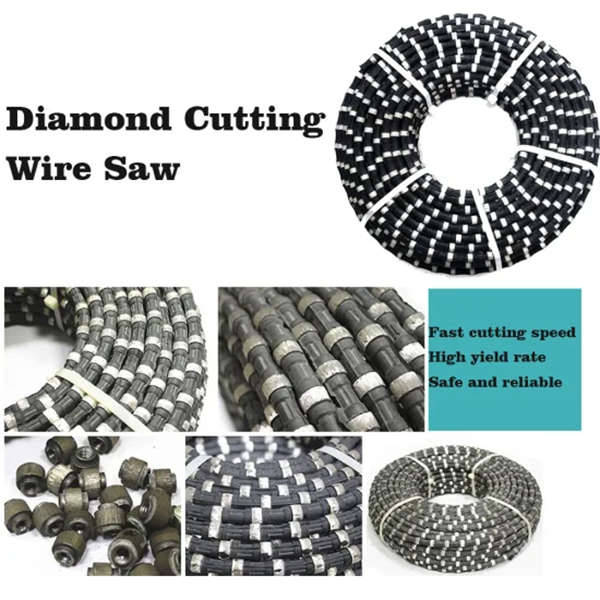

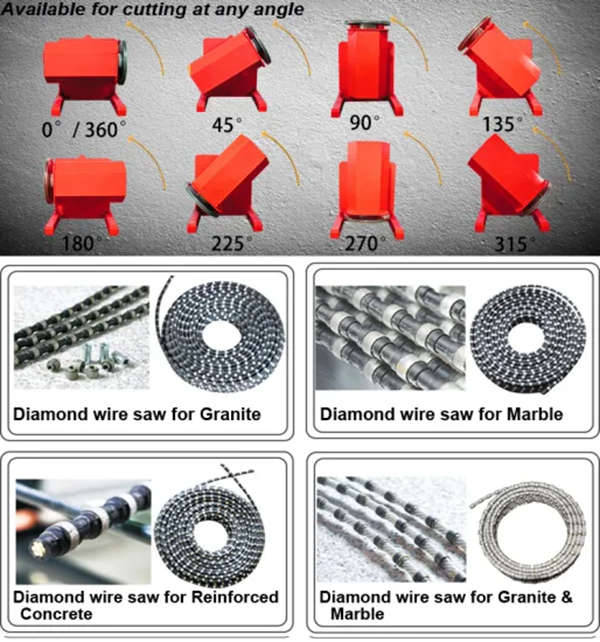

At the heart of the quarry diamond wire saw machine lies its innovative design. These machines utilize a thin, flexible wire embedded with diamond grains that act as cutting edges. As the wire moves at high speeds, it smoothly slices through rock without applying excessive force, reducing the risk of breakage. Furthermore, the adjustable tension system allows operators to maintain optimal cutting conditions, adapting to varying stone densities and hardness levels.

Applications of the Quarry Diamond Wire Saw Machine

From cutting granite in mountainous regions to extracting marble from open-pit mines, the quarry diamond wire saw machine finds extensive use across diverse geological settings. Its versatility makes it suitable for both large-scale industrial projects and smaller, more detailed work. In construction, these machines play a crucial role in preparing stone slabs for buildings, monuments, and decorative purposes, ensuring uniform thickness and smooth surfaces.

Maintenance and Operational Considerations for the Quarry Diamond Wire Saw Machine

To ensure optimal performance and longevity of the quarry diamond wire saw machine, regular maintenance is essential. This includes checking the wire for wear and tear, lubricating moving parts, and cleaning debris from the machine after each use. Proper training for operators is also critical, as understanding how to adjust cutting parameters based on material type can significantly impact productivity and safety.

Sustainability and Environmental Impact of the Quarry Diamond Wire Saw Machine

One often-overlooked aspect of the quarry diamond wire saw machine is its contribution to sustainable quarrying practices. By minimizing waste and reducing energy consumption during the cutting process, these machines help lower the environmental footprint of stone extraction. They also produce less dust and noise pollution, creating a healthier working environment and minimizing disturbances to nearby communities.

Future Prospects and Technological Advancements in Quarry Diamond Wire Saw Machines

As technology continues to evolve, so too does the quarry diamond wire saw machine. Future developments are likely to focus on enhancing automation capabilities, improving cutting speeds, and further refining the durability of the wire itself. Research into alternative materials for wire composition could lead to even more efficient and longer-lasting products. Moreover, integrating smart sensors and IoT (Internet of Things) technologies may enable real-time monitoring and predictive maintenance, taking the performance and reliability of these machines to new heights.

By investing in quarry diamond wire saw machines, companies not only gain access to state-of-the-art technology but also position themselves at the forefront of sustainable and efficient stone extraction practices. As demand for natural stones grows globally, these machines will undoubtedly continue to play a pivotal role in meeting market needs while preserving our planet’s valuable resources.

Request for Quotation

报错: 未找到这个表单