The Releated Products of Quarry Diamond Wire Saw Cost

Quarry Diamond Wire Saw Cost

Table of Contents

Quarry Diamond Wire Saw Cost: An In-depth Analysis

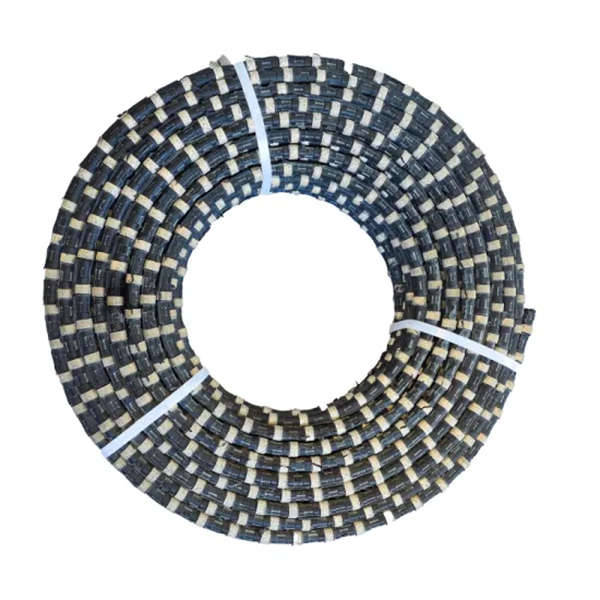

When it comes to the precision cutting of hard materials such as granite, marble, and other stones, diamond wire saws have become indispensable tools in quarries worldwide. However, the quarry diamond wire saw cost can vary significantly depending on several factors. Understanding these factors is crucial for making informed decisions that can impact your bottom line. This article delves into the various aspects affecting the cost of quarry diamond wire saws, providing insights that will help you make better purchasing decisions.

The Initial Investment in Quarry Diamond Wire Saws

The initial investment required for acquiring a quarry diamond wire saw is one of the primary concerns for many quarry operators. Costs can range from tens of thousands to hundreds of thousands of dollars, depending on the brand, model, and features. High-end models often come with advanced technology, increased durability, and better performance, which justifies their higher price tag. However, smaller operations might find mid-range or even refurbished models more suitable for their needs, balancing cost-effectiveness with functionality.

Maintenance and Operational Costs of Quarry Diamond Wire Saws

Beyond the initial purchase, ongoing maintenance and operational costs must be considered when assessing the total quarry diamond wire saw cost. Regular maintenance, including lubrication, inspection, and replacement of worn parts, is essential to keep the saw running smoothly. These activities require skilled labor and specialized tools, adding to the overall expenses. Additionally, operational costs like electricity, water for cooling, and the cost of the diamond wire itself contribute to the long-term financial commitment.

Impact of Efficiency on Quarry Diamond Wire Saw Cost

Efficiency plays a critical role in determining the true quarry diamond wire saw cost over its lifetime. More efficient machines can cut faster and with greater precision, reducing waste and increasing productivity. While they may carry a higher upfront cost, the savings realized through enhanced efficiency can quickly offset this expense. Furthermore, efficient machines tend to have lower energy consumption, which translates into reduced operational costs over time.

Influence of Brand and Quality on Quarry Diamond Wire Saw Cost

The brand and quality of a quarry diamond wire saw also influence its cost. Established brands often command premium prices due to their reputation for reliability and customer support. Higher-quality models typically last longer and perform better under demanding conditions, potentially offering better value despite their higher initial cost. Investing in a reputable brand can save money in the long run by minimizing downtime and repair costs.

Environmental Considerations Affecting Quarry Diamond Wire Saw Cost

Environmental regulations increasingly affect the quarry diamond wire saw cost. Modern saws are designed to meet stringent environmental standards, which can add to their price. However, these eco-friendly models often use less water and produce fewer pollutants, potentially qualifying your operation for government incentives or tax breaks. Considering these benefits alongside the direct costs provides a more comprehensive view of the financial impact.

Future Trends Impacting Quarry Diamond Wire Saw Cost

Looking ahead, technological advancements and market trends will continue to shape the quarry diamond wire saw cost landscape. Innovations in material science and manufacturing processes could lead to more affordable yet highly effective saws. Moreover, the growing emphasis on sustainability may drive the development of more environmentally friendly solutions, which could redefine cost structures within the industry.

Understanding all these elements is key to managing the quarry diamond wire saw cost effectively. By carefully evaluating each aspect, quarry managers can make strategic investments that align with their operational goals while staying within budget constraints.

Request for Quotation

报错: 未找到这个表单