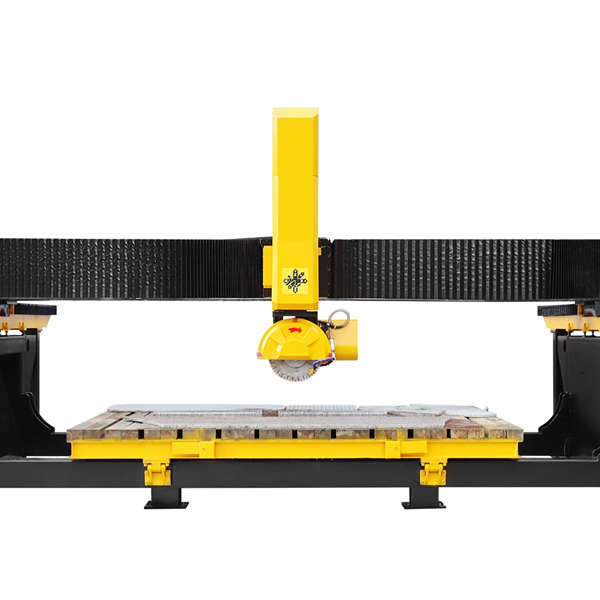

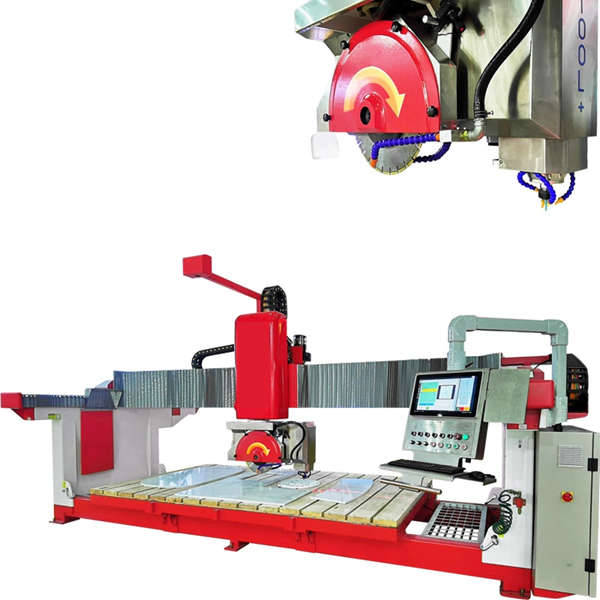

The Releated Products of Purpose Of Water Used With Ceramic Tile Saw

Purpose Of Water Used With Ceramic Tile Saw

Table of Contents

Purpose of Water Used with Ceramic Tile Saw

When it comes to cutting ceramic tiles, precision and safety are paramount. A ceramic tile saw is an indispensable tool for achieving clean, accurate cuts, especially when water is involved. But why exactly is water used with a ceramic tile saw? In this article, we’ll explore the multifaceted benefits of using water during the cutting process, from enhancing the quality of the cut to ensuring operator safety.

Cooling the Blade: Water’s Role in Maintaining Optimal Performance

One of the primary purposes of water in a ceramic tile saw setup is to cool the blade. As the diamond blade slices through the hard surface of ceramic tiles, friction generates significant heat. This heat can cause the blade to overheat, leading to premature wear or even damage. By continuously spraying water onto the blade and the tile being cut, the temperature is kept under control, ensuring that the blade remains sharp and effective. The water acts as a coolant, reducing thermal stress and prolonging the life of the cutting tool.

Reducing Dust: Creating a Safer Work Environment

Another critical function of water in the operation of a ceramic tile saw is dust suppression. Cutting ceramic tiles without water results in a cloud of fine dust particles that can pose serious health risks, including respiratory issues. The water mist captures these particles, preventing them from becoming airborne. This not only improves air quality in the workspace but also complies with occupational health and safety standards. Thus, the use of water significantly enhances the safety of the working environment for operators.

Enhancing Cut Quality: Achieving Smooth Edges and Precise Cuts

The use of water with a ceramic tile saw also contributes to the overall quality of the cut. By reducing heat buildup, water helps maintain the integrity of the blade, which in turn results in smoother edges and more precise cuts. Without proper cooling, the blade may become too hot, causing chipping or cracking along the cut line. The steady stream of water ensures a cleaner, more controlled cutting action, making it easier to achieve professional-looking results.

Lubricating the Cut: Facilitating Efficient Tile Cutting

Water serves as a natural lubricant between the blade and the tile surface. This lubrication reduces friction, allowing the blade to glide smoothly through the material. Less friction means less resistance, which translates into a more efficient cutting process. It also minimizes the risk of the blade binding or getting stuck, which could lead to uneven cuts or potential accidents. The lubricating effect of water ensures a smoother, faster, and safer cutting experience.

Extending Tool Life: Cost Savings Over Time

By protecting the blade from excessive heat and wear, water indirectly contributes to extending the life of your ceramic tile saw’s cutting tools. High-quality diamond blades can be quite expensive, so anything that helps prolong their lifespan is beneficial. Regular use of water during cutting operations can save you money in the long run by reducing the frequency of blade replacements. This is particularly important for professionals who rely on their tools daily.

Ensuring Compliance: Meeting Industry Standards

Lastly, the use of water with a ceramic tile saw is often required to meet industry standards and regulations regarding workplace safety and environmental protection. Many jurisdictions have strict rules governing the emission of dust and particulates during construction activities. Employers must provide a safe working environment, and using water to suppress dust is one effective way to comply with these requirements. Additionally, it demonstrates a commitment to sustainable practices by minimizing harmful emissions.

In conclusion, while water might seem like a simple addition to the process of cutting ceramic tiles, its role is multifaceted and crucial. From maintaining the performance and longevity of cutting tools to creating a safer work environment, water plays an indispensable part in the operation of a ceramic tile saw. Understanding its importance can help ensure better results and a more efficient workflow.

Request for Quotation

报错: 未找到这个表单