The Releated Products of Portable Diamond Wire Saw

Portable Diamond Wire Saw

Table of Contents

Portable Diamond Wire Saw: A Cutting Edge Solution

In the world of construction and demolition, precision and efficiency are paramount. This is where the portable diamond wire saw emerges as a game-changer. Its ability to cut through dense materials with unparalleled accuracy has made it indispensable for a range of applications. From cutting concrete and stone to slicing through reinforced materials, this tool stands out for its versatility and power.

Precision Cutting with a Portable Diamond Wire Saw

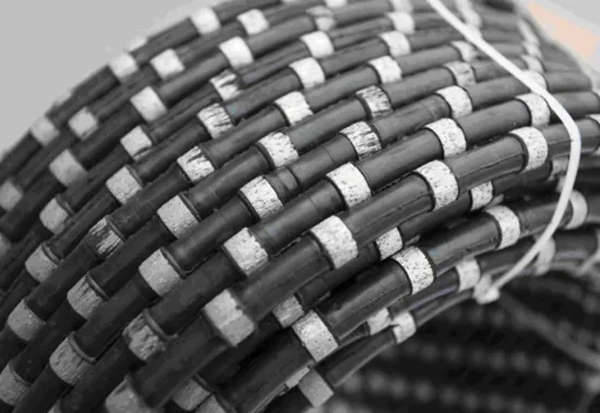

One of the most significant advantages of using a portable diamond wire saw is its precision. Unlike traditional methods, which can often result in uneven cuts or damage to surrounding areas, a diamond wire saw offers clean, straight cuts every time. This precision is achieved thanks to the continuous loop of diamond-impregnated wire that rotates around two or more pulleys. The result? A cutting tool capable of making incisions with minimal vibration and maximum control, ensuring that even the most intricate jobs are executed flawlessly.

Efficiency in Demolition with a Portable Diamond Wire Saw

When it comes to demolition projects, speed and safety are critical factors. Here again, the portable diamond wire saw excels. Its design allows for rapid cutting without compromising on safety standards. Because it operates silently compared to other tools, it’s ideal for use in noise-sensitive environments. Moreover, its compact size makes it easy to maneuver in tight spaces, enhancing both productivity and safety on the job site.

Versatility of a Portable Diamond Wire Saw

The portable diamond wire saw is not limited to just one type of material or application. It can effortlessly cut through various materials such as concrete, asphalt, brick, and even steel-reinforced structures. This versatility makes it an essential tool for contractors who need a single piece of equipment capable of handling diverse tasks efficiently. Whether you’re working on bridge removals, cutting windows into existing buildings, or performing underwater salvage operations, the diamond wire saw proves its worth across multiple industries.

Maintenance and Durability of a Portable Diamond Wire Saw

Given the harsh conditions under which these tools operate, durability is key. Fortunately, the portable diamond wire saw is built to last. High-quality components and robust construction ensure that it can withstand rigorous use over extended periods. Regular maintenance, including proper lubrication of moving parts and inspection of the wire for wear, helps keep the saw running smoothly. Additionally, replacement parts are readily available, reducing downtime and prolonging the life of the equipment.

Cost-Effectiveness of a Portable Diamond Wire Saw

While investing in a portable diamond wire saw might seem costly upfront, the long-term benefits far outweigh the initial expenditure. Its ability to increase productivity by speeding up the cutting process while maintaining high standards of quality can lead to significant savings in labor costs. Furthermore, the reduced risk of damage to surrounding areas means fewer materials wasted, contributing to overall cost-effectiveness.

Environmental Impact of a Portable Diamond Wire Saw

Considering the growing emphasis on sustainability within the construction industry, the portable diamond wire saw also scores points for its environmental friendliness. By minimizing waste and reducing the need for secondary operations to correct poor cuts, it supports greener practices. Additionally, its silent operation contributes to reducing noise pollution, making it suitable for use in densely populated urban areas without disturbing residents or wildlife.

In conclusion, the portable diamond wire saw represents a significant advancement in cutting technology, offering unmatched precision, efficiency, and versatility. As the construction industry continues to evolve, embracing innovative tools like the diamond wire saw will be crucial for staying competitive and meeting the increasing demands for sustainable building practices.

Request for Quotation

报错: 未找到这个表单