The Releated Products of Multi Wire Saw Diamond

Multi Wire Saw Diamond

Table of Contents

Multi Wire Saw Diamond: Precision Cutting for Advanced Materials

In the realm of industrial cutting, precision and efficiency are paramount. One technology that has revolutionized the way hard materials are sliced is the multi wire saw diamond system. This advanced machinery utilizes thin, diamond-coated wires to cut through materials such as silicon, sapphire, and other semiconductors with unparalleled accuracy and speed. Let’s delve into the world of multi wire saw diamond technology, exploring its applications, benefits, and the science behind its operation.

Multi Wire Saw Diamond: An Introduction

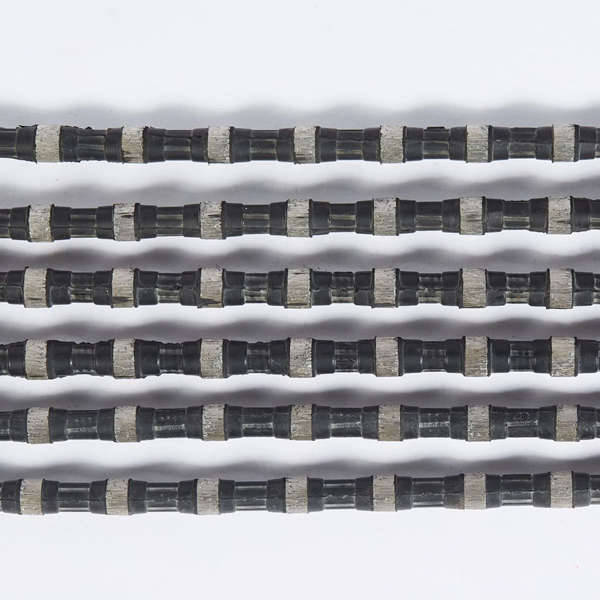

The multi wire saw diamond represents a significant leap forward from traditional blade-based cutting methods. By employing multiple parallel wires embedded with diamond particles, these systems can achieve cuts that are both faster and more precise. Each wire acts independently, allowing for simultaneous slicing of numerous pieces from a single block, thereby increasing productivity and reducing material waste.

How Multi Wire Saw Diamond Works

Understanding how a multi wire saw diamond operates provides insight into its capabilities and limitations. Essentially, the process begins by threading hundreds of steel wires between two large spools. These wires are then coated with a slurry containing water and micron-sized diamond particles. As the wires move back and forth under tension, they grind against the material being cut, effectively slicing it into thinner sections. The continuous motion and diamond grit ensure clean, straight cuts even through the hardest substances.

Benefits of Multi Wire Saw Diamond Technology

Adopting multi wire saw diamond technology offers several advantages over conventional cutting techniques. Firstly, the reduced width of the cutting medium (the wires) minimizes kerf loss—the material lost during the cutting process—resulting in higher yields from raw materials. Additionally, the ability to make multiple cuts simultaneously significantly boosts production rates. Lastly, the precision afforded by this method ensures uniformity across all slices, crucial for applications requiring exact dimensions.

Applications of Multi Wire Saw Diamond Systems

Multi wire saw diamond systems find extensive use across various industries where high-precision cutting is essential. In the semiconductor industry, these machines are indispensable for slicing wafers used in electronic devices. Similarly, in solar panel manufacturing, multi wire saws enable the efficient production of photovoltaic cells. Moreover, their application extends to cutting precious stones like diamonds and rubies, ensuring minimal wastage and maximum value extraction.

Maintenance and Operation of Multi Wire Saw Diamond Equipment

To ensure optimal performance and longevity of multi wire saw diamond machinery, proper maintenance and operational procedures must be followed. Regular cleaning of the wire and slurry system prevents clogging and maintains cutting efficiency. Calibration checks are also necessary to guarantee consistent quality across cuts. Training operators thoroughly on safety protocols and machine handling is vital given the high-speed nature of these operations.

Future Innovations in Multi Wire Saw Diamond Technology

As technology advances, so too does the potential of multi wire saw diamond systems. Research is ongoing into developing even thinner wires and more durable diamond coatings to further reduce kerf losses and increase cutting speeds. Integration with automation and AI could lead to smarter, self-adjusting systems capable of optimizing parameters based on material characteristics. Such developments promise to push the boundaries of what is possible with multi wire saw diamond technology, cementing its place as a cornerstone of modern industrial cutting processes.

By embracing the power of multi wire saw diamond technology, manufacturers can achieve new levels of efficiency and precision in their operations. As this technology continues to evolve, the possibilities for innovation and growth within industries relying on high-quality, precise cutting will only expand.

Request for Quotation

报错: 未找到这个表单