The Releated Products of Multi Diamond Wire Saw Machine

Multi Diamond Wire Saw Machine

Multi Diamond Wire Saw Machine: Precision Cutting for Industrial Applications

In the dynamic world of industrial cutting, precision and efficiency are paramount. The Multi Diamond Wire Saw Machine has emerged as a game-changer, offering unparalleled accuracy and speed in material cutting. This article explores the innovative features, applications, and benefits of using these machines, highlighting why they are essential tools for modern manufacturing processes.

Advantages of Using Multi Diamond Wire Saw Machines

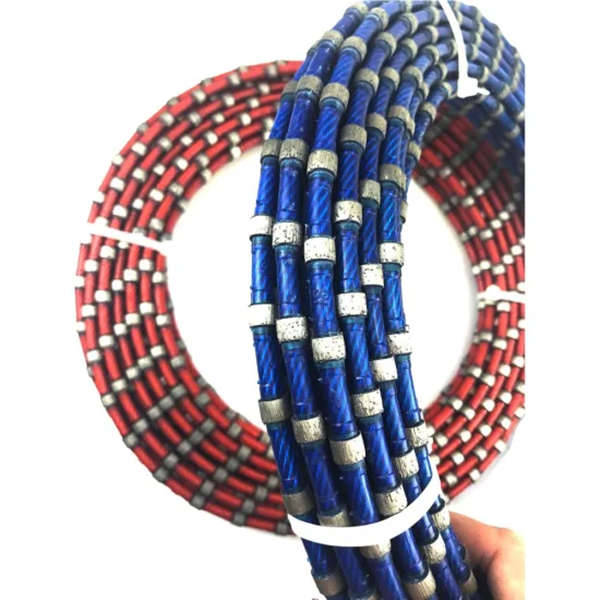

The Multi Diamond Wire Saw Machine stands out due to its ability to cut through hard materials like stone, concrete, and metals with exceptional precision. These machines use a thin wire embedded with diamond particles that rotate at high speeds, making clean cuts without producing excessive heat or dust. Additionally, their multi-wire configuration allows for simultaneous cutting, significantly reducing processing time and increasing productivity.

Key Components of a Multi Diamond Wire Saw Machine

Understanding the components of a Multi Diamond Wire Saw Machine is crucial for optimizing its performance. Typically, these systems consist of a robust frame, powerful motors, and a precisely engineered wire guide system. The diamond-impregnated wires are tensioned between spools and guided through the material by a series of pulleys. Advanced control systems ensure consistent tension and speed, maintaining the integrity of both the material being cut and the saw itself.

Applications of Multi Diamond Wire Saw Machines in Industry

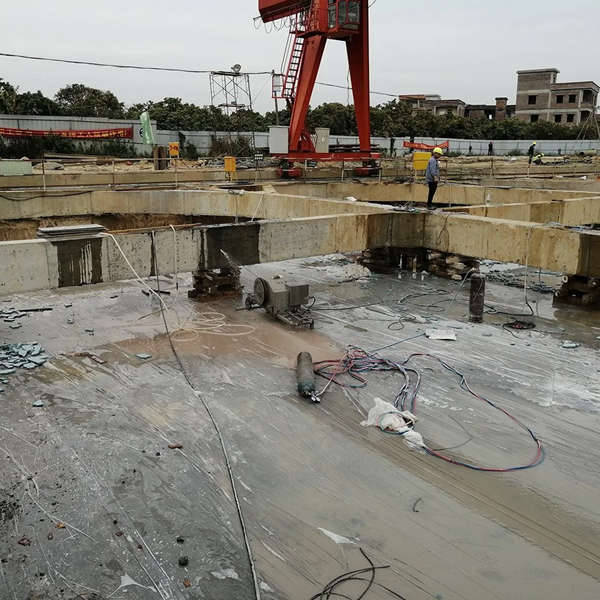

From construction sites to specialized manufacturing facilities, the Multi Diamond Wire Saw Machine finds application across various sectors. In construction, these machines excel at cutting reinforced concrete, enabling faster demolition and renovation projects. For manufacturers dealing with hard materials such as quartz or granite, the multi-wire saw offers a cost-effective solution for slab production. The versatility of these machines makes them indispensable in industries requiring precise and efficient cutting solutions.

Maintenance and Safety Considerations for Multi Diamond Wire Saw Machines

To ensure optimal performance and longevity of your Multi Diamond Wire Saw Machine, regular maintenance is essential. This includes inspecting and replacing worn wires, lubricating moving parts, and cleaning debris from the machine. Safety should also be a top priority when operating these powerful tools. Proper training on handling procedures, wearing protective gear, and following manufacturer guidelines can prevent accidents and injuries.

Cost-Effectiveness of Investing in Multi Diamond Wire Saw Machines

Despite the initial investment required, the Multi Diamond Wire Saw Machine proves cost-effective over time. Its ability to perform multiple cuts simultaneously reduces labor costs and increases output. Moreover, the precision of the cuts minimizes material waste, further enhancing profitability. For businesses looking to streamline operations and improve efficiency, this technology represents a valuable addition to their arsenal.

Future Innovations in Multi Diamond Wire Saw Technology

As technology advances, so too does the design and functionality of Multi Diamond Wire Saw Machines. Current research focuses on developing stronger diamond compounds, more durable wire materials, and smarter control systems. These advancements promise to make future models even more efficient, capable of handling tougher jobs with greater ease. As manufacturers continue to innovate, we can expect these machines to play an increasingly important role in shaping the future of industrial cutting practices.

By embracing the power and precision of the Multi Diamond Wire Saw Machine, industries worldwide stand to benefit from improved productivity, reduced costs, and enhanced safety standards. Whether you’re a small-scale operation or a large manufacturing plant, investing in this cutting-edge technology could be the key to unlocking new levels of efficiency and profitability.

Request for Quotation

报错: 未找到这个表单