The Releated Products of Mirage Diamond Wire Saw

Mirage Diamond Wire Saw

Table of Contents

The Precision of Mirage Diamond Wire Saws

In the realm of construction and industrial cutting, precision and efficiency are paramount. This is where the Mirage Diamond Wire Saw shines, offering unparalleled accuracy and speed in cutting through some of the toughest materials. Whether it’s for quarrying, bridge demolition, or structural renovation, these saws have become indispensable tools. Let’s delve into what makes them stand out and explore their various applications.

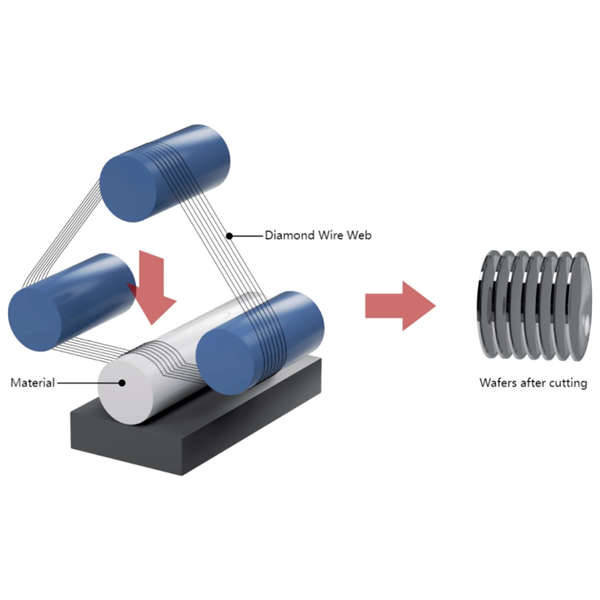

Efficiency in Cutting with Mirage Diamond Wire Saws

One of the most notable features of the Mirage Diamond Wire Saw is its efficiency. These saws use a thin wire embedded with diamond grains to cut through materials. The continuous motion of the wire allows for clean, precise cuts without the need for significant force. This method is particularly useful in environments where traditional saws might be too cumbersome or where noise and dust levels must be kept to a minimum.

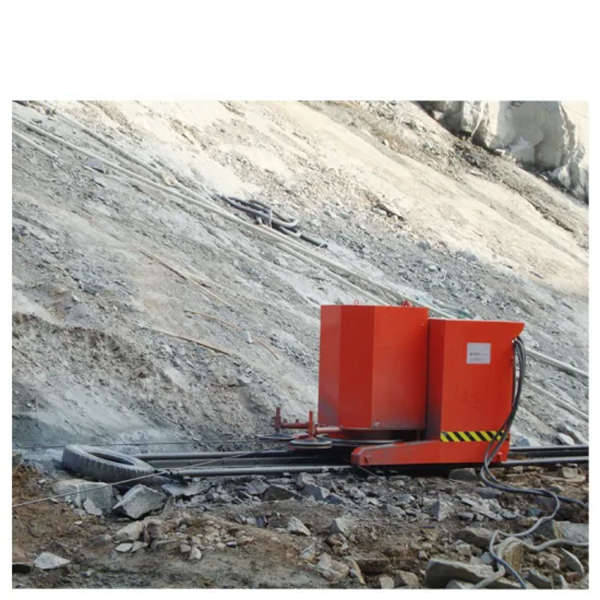

Applications of Mirage Diamond Wire Saws

From construction sites to quarries, the Mirage Diamond Wire Saw finds application across a wide range of industries. Its ability to make complex cuts, such as those required in the removal of bridge decks or the extraction of large blocks of stone from quarries, sets it apart from other cutting technologies. Additionally, these saws are invaluable during renovations where existing structures need to be modified with minimal disruption.

Benefits of Using Mirage Diamond Wire Saws

The benefits of using a Mirage Diamond Wire Saw extend beyond just its cutting capabilities. They offer several advantages that make them a preferred choice among professionals:

– Precision: The fine wire ensures exact cuts, reducing waste and improving overall project outcomes.

– Flexibility: Capable of making curved cuts and operating in tight spaces, these saws provide versatility unmatched by conventional cutting methods.

– Safety: By minimizing vibrations and reducing the risk of kickback, they enhance operator safety.

Maintenance and Care for Mirage Diamond Wire Saws

To ensure optimal performance and longevity, proper maintenance is crucial. Regular inspection of the wire for wear and tear, along with cleaning and lubrication of moving parts, can significantly extend the life of your saw. Following manufacturer guidelines for storage and handling also prevents damage and maintains the saw’s cutting efficiency.

Environmental Impact of Mirage Diamond Wire Saws

Considering the growing emphasis on sustainability within the industry, it’s worth noting how the Mirage Diamond Wire Saw contributes positively to this trend. Compared to traditional cutting methods, these saws produce less dust and noise pollution, making them environmentally friendly alternatives. Moreover, their precision reduces material waste, further enhancing their green credentials.

By combining advanced technology with practical design, the Mirage Diamond Wire Saw represents a step forward in the world of industrial cutting. Its ability to deliver on both performance and sustainability makes it a valuable asset for any operation looking to improve its cutting processes. Whether you’re a seasoned professional or new to the field, investing in a Mirage Diamond Wire Saw could transform the way you approach challenging projects.

Request for Quotation

报错: 未找到这个表单