The Releated Products of Marble Hand Cutter Machine

Marble Hand Cutter Machine

Table of Contents

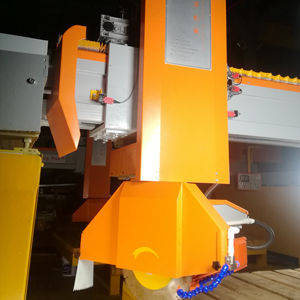

Understanding the Marble Hand Cutter Machine: Precision in Stone Crafting

In the world of stone crafting and renovation, precision and efficiency are paramount. One tool that has become indispensable for artisans and professionals alike is the marble hand cutter machine. This versatile piece of equipment allows for accurate cutting of marble, granite, and other hard stones, making it a valuable addition to any workshop or construction site. Whether you’re a seasoned professional or just starting out, understanding the features, benefits, and proper usage of a marble hand cutter machine can significantly enhance your projects.

Choosing the Right Marble Hand Cutter Machine

Selecting the appropriate marble hand cutter machine depends on several factors, including the frequency of use, types of materials being cut, and desired precision levels. For occasional DIY projects, a lightweight model with basic features might suffice. However, for commercial applications or frequent heavy-duty use, investing in a more robust, industrial-grade machine is essential. Key considerations include motor power, blade size, and ergonomic design.

Key Features of a High-Quality Marble Hand Cutter Machine

A high-quality marble hand cutter machine is designed to offer both power and control, ensuring clean cuts every time. Essential features include a powerful motor capable of handling tough materials, adjustable depth settings for precise cuts, and a dust collection system to maintain a clean working environment. Additionally, look for machines with durable construction and safety features such as blade guards and anti-vibration handles.

Maintaining Your Marble Hand Cutter Machine

To ensure optimal performance and longevity of your marble hand cutter machine, regular maintenance is crucial. This includes cleaning the machine after each use, lubricating moving parts, and inspecting the blade for wear and tear. Storing the machine in a dry place when not in use can also prevent rust and corrosion. By taking these simple steps, you’ll help extend the life of your tool while maintaining its cutting efficiency.

Safety Tips When Using a Marble Hand Cutter Machine

Safety should always be a top priority when operating any power tool, especially one as powerful as a marble hand cutter machine. Always wear protective gear such as safety glasses, gloves, and ear protection. Keep the work area well-lit and free from clutter. Follow manufacturer guidelines for blade selection and speed settings. Never force the tool through material; let the blade do the work to avoid kickback or loss of control.

Applications of the Marble Hand Cutter Machine

The versatility of the marble hand cutter machine makes it suitable for a wide range of applications beyond just marble. It can be used effectively on granite, limestone, and even some types of concrete. In construction, it’s invaluable for creating custom stone countertops, flooring tiles, and architectural elements. For artists and hobbyists, it opens up possibilities for sculpting and creating intricate designs in stone.

Advantages of Using a Marble Hand Cutter Machine

Using a marble hand cutter machine offers numerous advantages over traditional methods. Not only does it provide unparalleled precision and speed, but it also reduces physical strain on the user compared to manual tools. Its portability allows for easy transportation to job sites, while advanced models often come equipped with features like laser guides for even more accurate cutting. These benefits make it an essential tool for anyone working with stone materials.

By considering these aspects, you can choose the best marble hand cutter machine tailored to your specific needs, ensuring successful outcomes in all your stone cutting endeavors. Whether you’re tackling a large-scale project or a small DIY task, having the right tool makes all the difference in achieving professional results.

Request for Quotation

报错: 未找到这个表单