The Releated Products of Marble Cutting And Polishing

Marble Cutting And Polishing

Table of Contents

Marble Cutting: Precision and Artistry

In the realm of stone craftsmanship, marble cutting represents both an art form and a technical challenge. Marble, known for its natural beauty and versatility, requires specialized tools and techniques to transform it from raw blocks into elegant countertops, floors, and sculptures. The process begins with selecting the right equipment. For instance, diamond blades are essential for achieving clean, precise cuts in marble. These blades come in various sizes and bond strengths, tailored to specific applications ranging from thin veneers to thick slabs.

Polishing Techniques for Lustrous Marble Surfaces

Once the marble has been cut to size, polishing is the next critical step. This involves using progressively finer grits of abrasives to smooth out the surface, gradually revealing the stone’s inherent beauty. Polishing pads, typically made of diamonds or silicon carbide, are commonly used. They work by removing microscopic layers of marble, refining its texture until it reaches a high gloss finish. The choice of polishing compound can also affect the final appearance, with some enhancing the depth of color or providing a protective layer against stains.

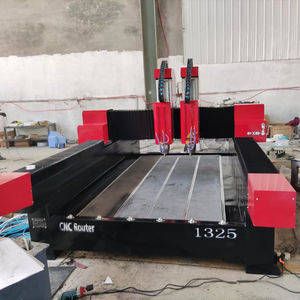

Marble Cutting Equipment: Essential Tools for Professionals

Professional marble cutters rely on a range of tools designed specifically for this task. Bridge saws, for example, offer unparalleled accuracy when cutting large slabs, while handheld wet saws provide flexibility for more intricate work. Water jets are another innovative technology gaining popularity due to their ability to make complex shapes and patterns with minimal material waste. Regardless of the tool chosen, safety must always be a priority. Dust collection systems and water cooling mechanisms help reduce health risks associated with cutting marble.

Choosing the Right Polishing Compound for Your Marble Project

The effectiveness of marble polishing largely depends on selecting the appropriate compounds. For most projects, a combination of diamond polishing pads and a marble polish enhancer will suffice. However, the exact type of compound needed may vary based on factors such as the hardness of the marble and the desired level of shine. Some compounds are formulated to bring out the natural colors of the stone, making them ideal for enhancing the visual appeal of decorative pieces.

Maintaining the Quality of Cut and Polished Marble

After the cutting and polishing processes are complete, proper maintenance becomes crucial for preserving the quality of the marble. Regular cleaning with pH-neutral cleaners prevents damage to the polished surface. Additionally, sealing the marble periodically helps protect against stains and etching, especially in high-use areas like kitchen countertops. Proper care not only maintains the aesthetic appeal of the marble but also extends its lifespan significantly.

Innovations in Marble Cutting and Polishing Technology

Advancements in technology continue to shape the future of marble cutting and polishing. Newer methods, such as robotic arms equipped with advanced sensors, allow for even greater precision and efficiency. Similarly, developments in abrasive materials lead to faster polishing times without compromising on the quality of the finish. As these technologies evolve, they promise to open up new possibilities in design and functionality, pushing the boundaries of what can be achieved with this timeless material.

By focusing on both traditional techniques and modern innovations, professionals in the industry can ensure that each piece of marble is treated with the care and attention it deserves, resulting in stunning finished products that stand the test of time.

Request for Quotation

报错: 未找到这个表单