The Releated Products of Marble Cutter Grinder

Marble Cutter Grinder

Table of Contents

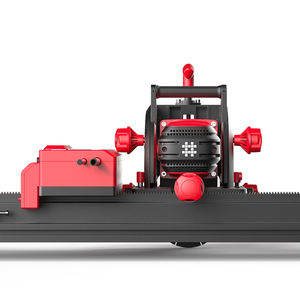

Understanding the Versatility of Marble Cutter Grinders

Marble cutter grinders have become indispensable tools in the world of construction and stonework. These powerful machines combine precision with strength, making them ideal for cutting and grinding marble, granite, and other hard surfaces. Whether you’re a professional craftsman or a DIY enthusiast, understanding the capabilities and features of these tools can greatly enhance your work efficiency and quality.

Selecting the Right Marble Cutter Grinder

When choosing a marble cutter grinder, several factors come into play. Consider the size of the projects you typically undertake, the power requirements, and the specific features that will make your job easier. For instance, a larger diameter blade might be necessary for bigger cuts, while adjustable handles and ergonomic designs can provide better control and reduce fatigue during extended use.

Maintaining Your Marble Cutter Grinder

Regular maintenance is crucial to keep your marble cutter grinder performing at its best. This includes cleaning the tool after each use, checking for any signs of wear and tear, and replacing parts as needed. Lubricating moving components helps prevent rust and ensures smooth operation. By investing time in proper care, you extend the life of your tool and maintain its cutting efficiency.

Safety Tips for Using a Marble Cutter Grinder

Safety should always be a top priority when operating any power tool, especially one as potent as a marble cutter grinder. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Ensure that the area around you is clear of debris and bystanders before starting work. Familiarize yourself with the manufacturer’s instructions and recommended practices to avoid accidents and injuries.

Advanced Features of Modern Marble Cutter Grinders

Innovation in tool technology has led to the development of advanced features in modern marble cutter grinders. Some models now come equipped with dust collection systems that help maintain a cleaner workspace, reducing health risks associated with airborne particles. Others boast variable speed settings, allowing users to adjust the cutting pace according to material hardness and project needs.

Applications Beyond Basic Cutting and Grinding

While primarily designed for cutting and grinding marble, these versatile tools can tackle a variety of applications. They are often used for polishing edges, creating intricate designs, and even removing old adhesives or coatings from surfaces. The right attachments and accessories can transform your basic marble cutter grinder into a multi-functional workshop companion.

Conclusion: Investing in Quality for Lasting Performance

Investing in a high-quality marble cutter grinder not only ensures superior performance but also represents a long-term investment in your craft or business. With the right tool at hand, tackling complex projects becomes more manageable, and the results speak for themselves. As you explore different models and features, keep in mind the importance of reliability, durability, and user-friendliness to find the perfect fit for your needs.

Request for Quotation

报错: 未找到这个表单