The Releated Products of Marble Block Cutting Machine

Marble Block Cutting Machine

Table of Contents

Understanding the Core Functionality of Marble Block Cutting Machines

In the world of stone processing, precision and efficiency are paramount. This is where marble block cutting machines come into play, revolutionizing how quarries and workshops operate. These machines are designed to cut through solid blocks of marble with unparalleled accuracy and speed, ensuring that every piece produced meets the highest standards of quality.

Technological Advancements in Marble Block Cutting Machines

Over the years, technological advancements have significantly enhanced the capabilities of marble block cutting machines. Innovations such as computer numerical control (CNC) systems have allowed for more precise cuts, reducing wastage and increasing productivity. Moreover, the integration of laser technology enables operators to achieve intricate designs and patterns that were previously impossible or extremely difficult to produce using traditional methods.

Types of Marble Block Cutting Machines Available Today

There are various types of marble block cutting machines available on the market, each suited to different needs and applications. Bridge saws, for instance, are widely used due to their versatility and ability to handle large slabs efficiently. Wire saw machines, on the other hand, excel in cutting softer stones like marble, offering smooth surfaces without chipping or cracking. Additionally, circular blade saws provide another option, particularly useful when working with smaller pieces or requiring straight cuts.

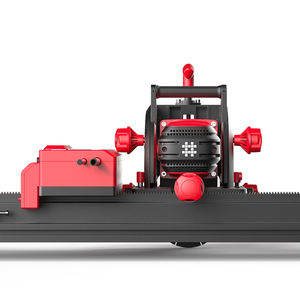

Key Components of a High-Quality Marble Block Cutting Machine

To ensure optimal performance and longevity, it’s crucial to understand the key components that make up a high-quality marble block cutting machine. The blade, being one of the most critical parts, must be made from durable materials capable of withstanding intense pressure and friction. The motor powers the blade and should have sufficient strength to drive through hard materials consistently. Finally, the frame and structure need to be robust enough to maintain stability during operation, preventing vibrations that could compromise the accuracy of the cut.

Maintenance Tips for Extending the Life of Your Marble Block Cutting Machine

Regular maintenance is essential for keeping your marble block cutting machine running smoothly and extending its lifespan. This includes cleaning the machine after each use to remove any debris or dust that may have accumulated. Lubricating moving parts helps reduce wear and tear, while inspecting the blade regularly ensures it remains sharp and effective. Lastly, following the manufacturer’s guidelines for operation and maintenance can prevent many common issues and keep your machine functioning at peak performance.

Choosing the Right Marble Block Cutting Machine for Your Business

Selecting the right marble block cutting machine depends on several factors, including the size of your operation, the types of projects you typically undertake, and your budget constraints. Smaller businesses might benefit more from compact models that offer flexibility and ease of use. Larger enterprises, however, may require industrial-grade machines capable of handling high-volume production demands. Consider consulting with industry experts or experienced professionals who can provide insights tailored to your specific requirements.

By investing in a reliable marble block cutting machine and maintaining it properly, businesses can achieve superior results while maximizing efficiency and profitability. Whether you’re just starting out or looking to upgrade your current setup, these considerations will help guide you towards making an informed decision that supports your long-term goals within the stone processing industry.

Request for Quotation

报错: 未找到这个表单