The Releated Products of Marble And Granite Cutting Machine

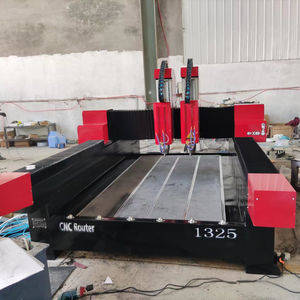

Marble And Granite Cutting Machine

Table of Contents

Introducing the Precision of Marble And Granite Cutting Machines

In the world of stone crafting, precision and efficiency are paramount. This is where marble and granite cutting machines come into play, offering unparalleled accuracy and speed. These specialized tools have revolutionized the industry, allowing artisans and manufacturers to work with these hard materials more effectively than ever before.

The Evolution of Marble And Granite Cutting Technology

Over the years, the technology behind marble and granite cutting machines has seen significant advancements. Early models were often bulky and required considerable manual effort. Today’s machines, however, are sleek, automated, and capable of handling both small-scale and large-scale projects with ease. Innovations such as water jet cutting and laser technology have further enhanced their capabilities, making them indispensable for modern stonemasons and construction companies alike.

Key Features of Advanced Marble And Granite Cutting Machines

When shopping for a marble and granite cutting machine, several features stand out as essential. First, the motor power must be sufficient to cut through dense materials without overheating. Additionally, adjustable cutting angles and speeds allow for versatility in tackling various projects. Safety features such as blade guards and emergency stop buttons are also critical components that protect operators during use.

Applications of Marble And Granite Cutting Machines in Various Industries

From architecture to sculpture, marble and granite cutting machines find applications across numerous fields. In construction, they’re used for creating countertops, flooring tiles, and decorative elements. Sculptors rely on these machines to shape raw blocks into intricate works of art. Even in the memorial industry, these tools help craft headstones and monuments with precision and detail.

Benefits of Using Marble And Granite Cutting Machines

One of the primary benefits of using marble and granite cutting machines is increased productivity. Automated processes reduce the time needed to complete tasks compared to traditional methods. There’s also a marked improvement in quality, as these machines ensure clean, straight cuts every time. Moreover, they minimize material waste by allowing for precise measurements and adjustments, thus saving costs over time.

Maintenance Tips for Marble And Granite Cutting Machines

To keep your marble and granite cutting machine functioning optimally, regular maintenance is crucial. This includes cleaning the machine after each use to prevent residue buildup, checking for worn parts like blades or belts, and lubricating moving components to ensure smooth operation. Following manufacturer guidelines for service intervals can also extend the lifespan of your equipment significantly.

Choosing the Right Marble And Granite Cutting Machine for Your Needs

Selecting the appropriate marble and granite cutting machine depends largely on the specific requirements of your project. Consider factors such as the size of the workpiece, the complexity of the cuts needed, and your budget. Consulting with professionals who understand the nuances between different models can provide valuable insights, helping you make an informed decision that best suits your business goals.

Request for Quotation

报错: 未找到这个表单