The Releated Products of Maca Stone Cutting Machine

Maca Stone Cutting Machine

Table of Contents

Maca Stone Cutting Machine: Precision, Efficiency, and Durability

Maca Stone Cutting Machine: An Introduction to Its Applications

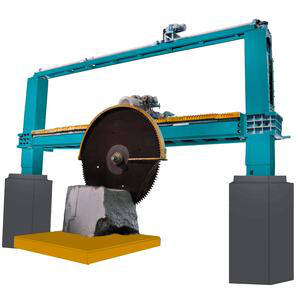

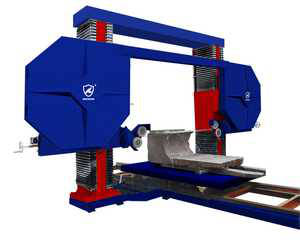

In the dynamic world of stone processing, precision and efficiency are paramount. The Maca stone cutting machine has emerged as a game-changer, offering unparalleled accuracy and speed in cutting a wide range of stones. From granite and marble to quartz and limestone, this versatile machine can handle various materials with ease. Designed for both commercial and industrial applications, it provides a robust solution for stonemasons, architects, and construction professionals seeking high-quality cuts.

Features of the Maca Stone Cutting Machine That Set It Apart

The Maca stone cutting machine boasts several features that distinguish it from other machines on the market. A powerful motor, coupled with advanced blade technology, ensures clean cuts every time. Its adjustable cutting angle allows for versatility in creating intricate designs and patterns. Moreover, the machine’s sturdy construction ensures durability, making it a reliable investment for businesses looking to enhance their production capabilities.

Benefits of Using a Maca Stone Cutting Machine for Your Business

Investing in a Maca stone cutting machine can significantly improve your business operations. By reducing waste and increasing productivity, it helps you take on larger projects with confidence. The machine’s ergonomic design also enhances user safety, reducing the risk of workplace injuries. Furthermore, its low maintenance requirements contribute to cost savings over time, making it an economical choice for small and large enterprises alike.

How the Maca Stone Cutting Machine Enhances Productivity

One of the key advantages of using a Maca stone cutting machine is its ability to enhance productivity. With its fast cutting speeds and precise movements, it can process multiple pieces of stone within a short period. This efficiency not only speeds up project completion times but also allows for better management of resources. Additionally, the machine’s user-friendly interface simplifies operation, enabling even novice operators to achieve professional results quickly.

Maintenance Tips for Your Maca Stone Cutting Machine

To ensure your Maca stone cutting machine operates at peak performance, regular maintenance is essential. Cleaning the machine after each use prevents the buildup of dust and debris that could interfere with its functionality. Lubricating moving parts helps reduce wear and tear, extending the machine’s lifespan. Periodic inspections by a certified technician can identify potential issues before they become major problems, ensuring uninterrupted service.

Choosing the Right Maca Stone Cutting Machine for Your Needs

When selecting a Maca stone cutting machine, consider factors such as the types of materials you will be working with, the size of your projects, and your budget constraints. Models designed for heavy-duty use feature more powerful motors and larger cutting capacities, ideal for industrial settings. For smaller operations, compact versions offer sufficient power while taking up minimal space. Consulting with a knowledgeable sales representative can help guide you towards the best option for your specific requirements.

Conclusion: Elevate Your Stone Cutting Process with Maca

By integrating a Maca stone cutting machine into your workflow, you’re investing in a tool that combines modern technology with proven engineering principles. Whether you’re looking to streamline production processes or expand your business capabilities, this machine delivers consistent performance and quality. As demand for customized stonework continues to grow, having the right equipment can make all the difference in staying competitive and meeting customer expectations.

Request for Quotation

报错: 未找到这个表单