The Releated Products of Laboratory Diamond Wire Saw Cutting Machine

Laboratory Diamond Wire Saw Cutting Machine

Table of Contents

Precision and Efficiency: The Role of Laboratory Diamond Wire Saw Cutting Machines

Understanding Laboratory Diamond Wire Saw Cutting Machines

In the realm of material science and engineering, precision cutting plays a pivotal role in achieving accurate results and maintaining the integrity of samples. Laboratory diamond wire saw cutting machines have emerged as indispensable tools, offering unparalleled accuracy and efficiency in slicing through a variety of materials, from metals and ceramics to composites and geological specimens.

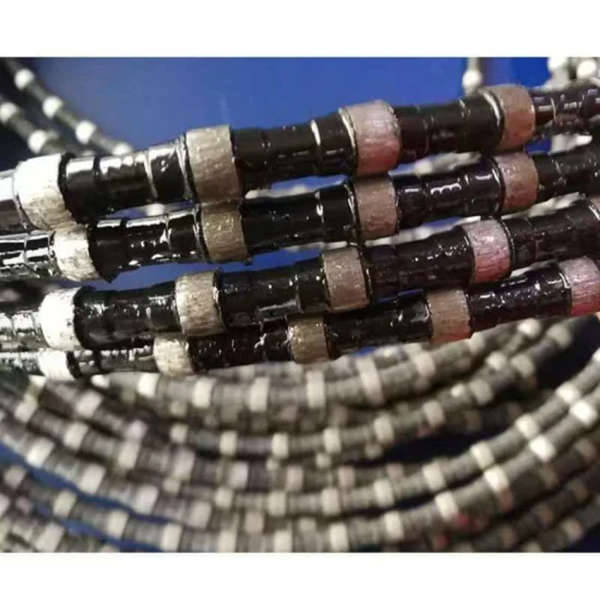

These machines utilize thin wires embedded with diamond particles, which act as a cutting tool. The diamond segments are strategically placed along the wire to ensure effective cutting even through the hardest materials. This method not only reduces the risk of sample damage but also allows for intricate cuts with minimal effort.

Key Features of Laboratory Diamond Wire Saw Cutting Machines

When selecting a laboratory diamond wire saw cutting machine, several key features should be considered:

– Precision: High-precision linear guides and ball screws enable precise positioning and control.

– Versatility: The ability to handle different materials and thicknesses without compromising on quality.

– Durability: Robust construction ensures long-lasting performance even under demanding conditions.

– Ease of Use: User-friendly interfaces and automated functions simplify operation and maintenance.

Such features collectively contribute to the overall efficiency and reliability of these machines, making them ideal for both research and industrial applications.

Applications of Laboratory Diamond Wire Saw Cutting Machines

The versatility of laboratory diamond wire saw cutting machines makes them suitable for a wide range of applications across various industries:

– Material Science: Preparing samples for analysis and testing.

– Semiconductor Manufacturing: Cutting silicon wafers with high accuracy.

– Geological Studies: Slicing rock and mineral samples for detailed examination.

– Medical Research: Creating precise sections of biological materials.

Each application benefits from the machine’s ability to produce clean, accurate cuts, essential for obtaining reliable data and results.

Benefits of Using Laboratory Diamond Wire Saw Cutting Machines

Investing in a laboratory diamond wire saw cutting machine offers numerous advantages over traditional cutting methods:

– Enhanced Accuracy: Achieve consistent and repeatable cuts every time.

– Reduced Waste: Minimize material loss during the cutting process.

– Increased Productivity: Faster cutting speeds lead to higher throughput.

– Improved Safety: Enclosed design and safety features protect operators from hazards.

These benefits translate into cost savings, improved workflow, and better overall outcomes for laboratories and manufacturing facilities alike.

Maintenance and Care for Laboratory Diamond Wire Saw Cutting Machines

To ensure optimal performance and longevity, regular maintenance is crucial for laboratory diamond wire saw cutting machines:

– Cleaning: Regularly clean the machine to remove debris and prevent wear.

– Lubrication: Apply lubricants to moving parts to reduce friction and extend life.

– Inspection: Periodically inspect components for signs of damage or wear.

– Calibration: Regularly calibrate the system to maintain cutting accuracy.

Proper care not only enhances the machine’s durability but also ensures continued high-quality performance.

Future Trends in Laboratory Diamond Wire Saw Cutting Technology

As technology advances, so does the evolution of laboratory diamond wire saw cutting machines. Emerging trends include:

– Automation: Increased integration of robotic systems for unattended operation.

– Connectivity: Enhanced IoT capabilities for remote monitoring and diagnostics.

– Sustainability: Development of more eco-friendly materials and processes.

– Customization: Tailored solutions designed to meet specific client needs and requirements.

These developments promise to further streamline operations and push the boundaries of what’s possible with this powerful cutting technology.

Request for Quotation

报错: 未找到这个表单