The Releated Products of How Saw For Ceramic

How Saw For Ceramic

Table of Contents

Choosing the Right Saw for Ceramic: Precision and Durability

When it comes to cutting ceramic tiles or slabs, having the right tool is crucial. A saw for ceramic must be capable of delivering precise cuts while maintaining durability over time. Whether you’re a professional contractor or a DIY enthusiast, understanding the features and types of ceramic saws can make all the difference in your project’s outcome.

Types of Saws for Ceramic: Wet vs. Dry Cutting

The first decision when selecting a saw for ceramic involves choosing between wet and dry cutting methods. Wet saws use water to cool the blade and reduce dust during the cutting process, making them ideal for prolonged use and larger projects. On the other hand, dry saws do not require water and are more portable, suited for smaller jobs where mobility is key. Both options have their advantages, depending on the specific requirements of your project.

Blade Selection for Your Ceramic Saw

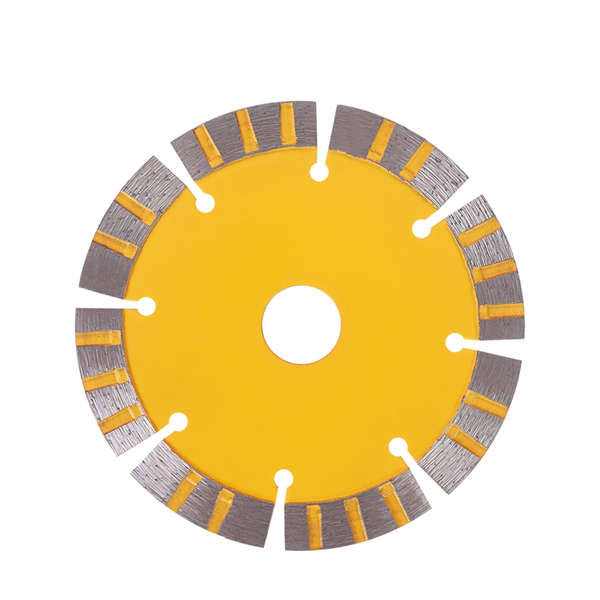

Another critical factor in choosing a saw for ceramic is the type of blade used. Diamond blades are the most common choice due to their ability to cut through hard materials like ceramic without chipping or cracking. These blades come in different bond strengths and segment heights, which affect their performance on various ceramic materials. A softer bond is better for harder ceramics, while a harder bond works well on softer ceramics.

Safety Measures When Using a Saw for Ceramic

Safety should always be a priority when operating any power tool, especially a saw for ceramic. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask. If using a wet saw, ensure that the area is well-ventilated to avoid inhaling mist particles. Familiarize yourself with the manufacturer’s instructions and recommended operating procedures to prevent accidents and ensure efficient cutting.

Maintenance and Care of Your Ceramic Saw

Proper maintenance is essential to prolong the life of your saw for ceramic and maintain its cutting efficiency. After each use, clean the saw thoroughly, removing any debris or residue from the blade and other components. Store the saw in a dry place, away from extreme temperatures. Regularly inspect the blade for signs of wear or damage; replace it if necessary to avoid compromising the quality of your work.

Tips for Achieving Precise Cuts with Your Ceramic Saw

Achieving accurate and clean cuts with a saw for ceramic requires both skill and the right technique. Start by marking the tile clearly with a pencil or chalk line as a guide. Use clamps or a steady hand to secure the material being cut, reducing the risk of movement or breakage. Adjust the depth of the blade so that it cuts through the full thickness of the ceramic, ensuring a complete and smooth cut. Practice makes perfect, so don’t be discouraged if it takes a few tries to get the hang of it.

By considering these aspects when choosing and using a saw for ceramic, you’ll be well-equipped to tackle any project with confidence. Whether renovating a bathroom or installing a new kitchen backsplash, investing in a high-quality saw will save you time, effort, and money in the long run. Remember, precision and durability are key when working with ceramics, so choose wisely and enjoy your crafting!

Request for Quotation

报错: 未找到这个表单