The Releated Products of Hole Saws For Drilling Ceramic

Hole Saws For Drilling Ceramic

Table of Contents

Hole Saws for Drilling Ceramic: Precision Tools for Perfect Holes

When it comes to drilling ceramic materials, whether it’s for tiles, sinks, or other home improvement projects, having the right tools can make all the difference. One such essential tool is a hole saw designed specifically for ceramic. These specialized hole saws provide clean, precise cuts without chipping or cracking the material. This article will guide you through the world of hole saws for drilling ceramic, helping you choose the best option for your next project.

Selecting the Right Hole Saw for Ceramic Applications

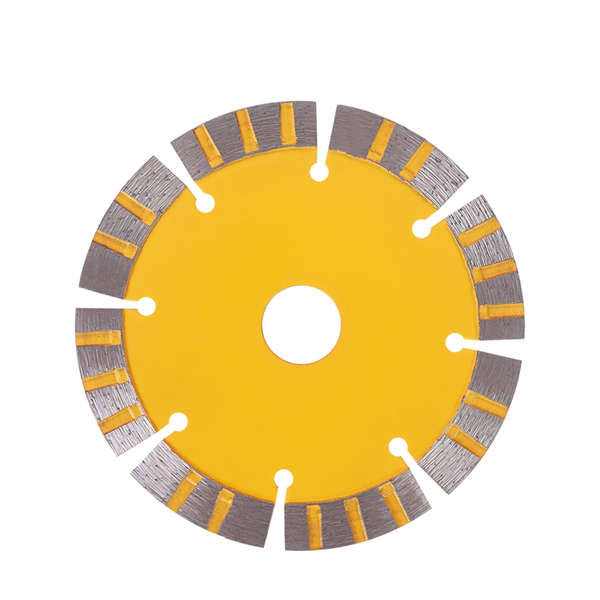

Choosing the correct hole saw for drilling ceramic is crucial for achieving professional results. Consider factors like the material of the drill bit, its size, and compatibility with your power drill. Diamond-coated hole saws are particularly effective because they can easily penetrate hard surfaces like ceramics and porcelain without overheating or dulling quickly. They also tend to produce smoother edges compared to standard bi-metal hole saws.

Preparing Your Ceramic Surface Before Drilling

Before using a hole saw for drilling ceramic, it’s important to prepare the surface properly. Start by marking the exact spot where you want to drill using a pencil or marker. Apply masking tape over this area; this step helps prevent the ceramic from cracking as the drill bit makes initial contact. Additionally, ensure that the ceramic piece is securely clamped or held down to avoid movement during the drilling process, which could result in uneven holes or damage to the material.

Techniques for Using Hole Saws on Ceramic Materials

Using a hole saw for drilling ceramic requires some specific techniques to ensure optimal performance and longevity of the tool. Begin by applying gentle pressure when starting the drill; too much force can cause the bit to skid or chip the surface. It’s also advisable to use water as a coolant, especially when working with diamond-tipped hole saws. This not only prolongs the life of the tool but also reduces dust and keeps the work area cleaner.

Maintaining Your Hole Saw After Drilling Ceramic

Proper maintenance of your hole saw for drilling ceramic ensures that it remains in top condition for future use. Clean the hole saw thoroughly after each use to remove any ceramic debris or dust. Store it in a dry place away from moisture and extreme temperatures. Periodically inspect the cutting edge for signs of wear or damage; replacing worn-out hole saws is critical for maintaining safety and efficiency during operations.

Common Challenges When Drilling Ceramic with Hole Saws

Despite using the appropriate hole saw for drilling ceramic, challenges may still arise. One common issue is overheating, which can be mitigated by using adequate lubrication and taking frequent breaks to let the tool cool down. Another problem is vibration, leading to imprecise holes. To address this, ensure that your drill press or hand-held drill is set up correctly and that you’re using the recommended speed settings for ceramic materials.

Advantages of Using Specialized Hole Saws for Ceramic Projects

Investing in a quality hole saw for drilling ceramic offers several advantages over generic hole saws. These specialized tools provide better control and accuracy, making them ideal for delicate tasks such as installing bathroom fixtures or creating custom tile designs. They also reduce the risk of damaging expensive ceramic pieces, saving both time and money in the long run.

By understanding how to select, prepare, use, maintain, and troubleshoot hole saws for drilling ceramic, you’ll be well-equipped to tackle any ceramic-related project with confidence and precision. Whether you’re a DIY enthusiast or a professional contractor, these tips will help ensure that every hole you drill is as perfect as possible.

Request for Quotation

报错: 未找到这个表单