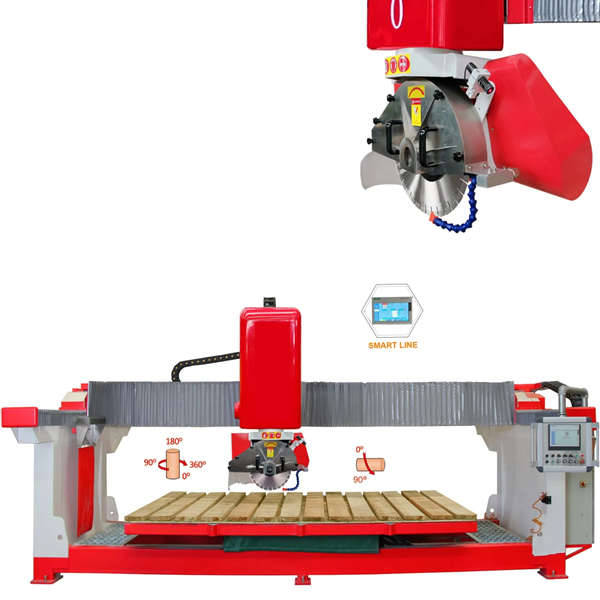

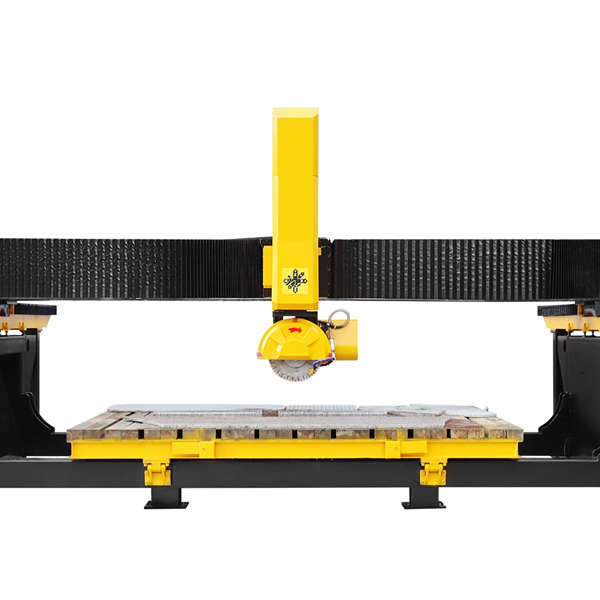

The Releated Products of Hole Saw For Drilling Ceramic Tile

Hole Saw For Drilling Ceramic Tile

Choosing the Right Hole Saw for Drilling Ceramic Tile

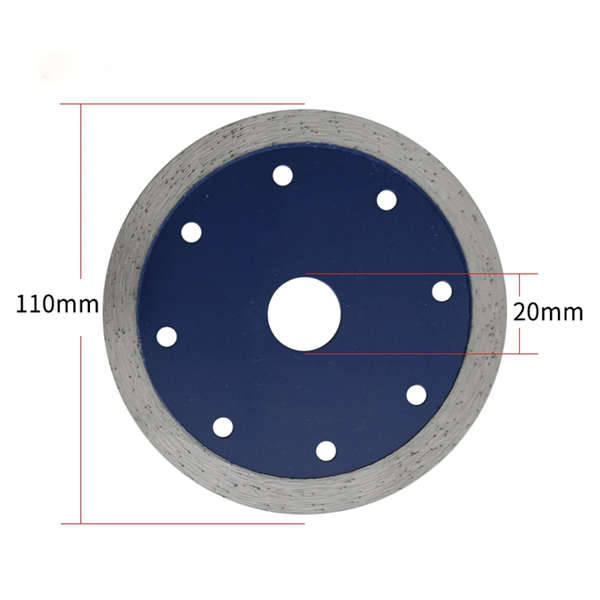

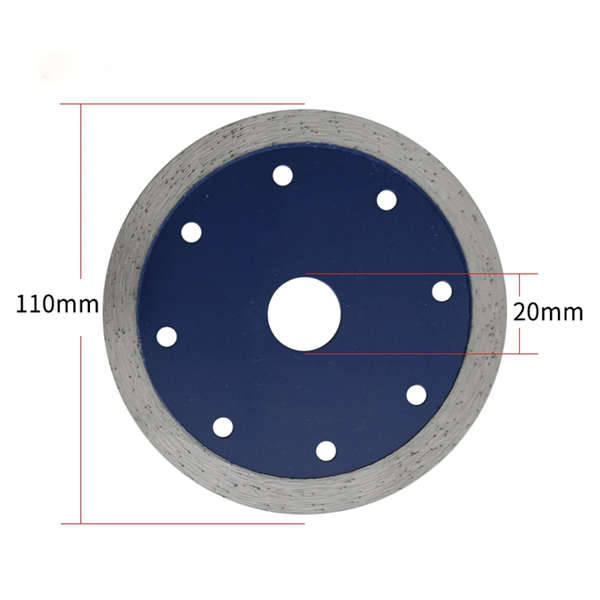

When it comes to drilling ceramic tile, having the right tools can make all the difference. One of the most important tools you’ll need is a hole saw. A hole saw for drilling ceramic tile must be robust enough to handle the hardness and thickness of the material while ensuring clean, precise cuts. This article will guide you through selecting and using a hole saw designed specifically for ceramic tiles.

Selecting a High-Quality Hole Saw for Drilling Ceramic Tile

Choosing a high-quality hole saw for drilling ceramic tile involves considering several factors such as the material of the drill bit, its size, and the type of coating used. Diamond-coated hole saws are particularly popular due to their durability and ability to cut through tough materials like ceramic without chipping or cracking. Additionally, these tools often come in various sizes, allowing users to create holes of different diameters depending on the project requirements.

Preparing Your Tools Before Using a Hole Saw for Drilling Ceramic Tile

Before you start drilling, ensure that your hole saw for drilling ceramic tile is properly prepared. Clean the drill bit thoroughly to remove any debris that might interfere with the cutting process. It’s also crucial to check the condition of the bit; dull or damaged bits can lead to poor performance and may even damage the tile. Finally, secure the tile firmly on a stable surface to prevent movement during drilling.

Techniques for Efficiently Using a Hole Saw for Drilling Ceramic Tile

Using a hole saw for drilling ceramic tile efficiently requires some technique. Start by marking the exact spot where you want to drill using a pencil or marker. Apply gentle pressure when beginning to drill, increasing it gradually as the bit penetrates the surface. Maintaining a steady pace is key to achieving smooth, clean holes. It’s advisable to use water periodically to cool the bit and reduce friction, which helps extend the life of your tool and improves the quality of the cut.

Troubleshooting Common Issues When Using a Hole Saw for Drilling Ceramic Tile

Even with proper preparation and technique, issues can arise when drilling ceramic tiles. One common problem is overheating of the hole saw for drilling ceramic tile, which can lead to premature wear or even breakage of the drill bit. To avoid this, ensure adequate cooling by applying water regularly. Another issue is chipping around the edges of the drilled hole. This can often be prevented by starting the drill slowly and ensuring that the tile is well-supported from behind.

Cleaning and Maintaining Your Hole Saw for Drilling Ceramic Tile

Proper maintenance of your hole saw for drilling ceramic tile is essential for longevity and continued performance. After each use, clean the drill bit to remove any residue. Store it in a dry place away from moisture and extreme temperatures. Periodically inspect the bit for signs of wear or damage, replacing it if necessary. Regular maintenance not only prolongs the life of your tool but also ensures that it remains effective for future projects.

Conclusion

Drilling ceramic tiles can be challenging without the right tools and techniques. By choosing a suitable hole saw for drilling ceramic tile, preparing your tools correctly, employing efficient drilling methods, troubleshooting common issues, and maintaining your equipment, you can achieve professional results every time. Whether you’re a DIY enthusiast or a professional contractor, investing in a quality hole saw for drilling ceramic tile is a smart decision that will pay off in terms of both time saved and superior workmanship.

Request for Quotation

报错: 未找到这个表单