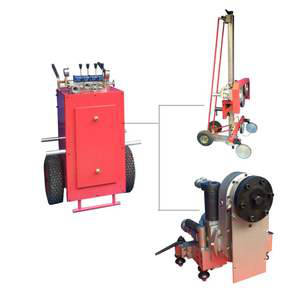

The Releated Products of Granite Stone Cutting Tools

Granite Stone Cutting Tools

Table of Contents

Granite Stone Cutting Tools: Precision, Durability, and Efficiency

In the world of construction and stonework, granite stands out as one of the most challenging materials to work with due to its hardness and durability. To effectively cut and shape this beautiful yet unforgiving stone, specialized tools are required. Granite stone cutting tools have evolved significantly over the years, adapting to meet the demands of both artisans and large-scale operations.

Choosing the Right Granite Stone Cutting Tools

When it comes to selecting granite stone cutting tools, professionals must consider several factors including the type of project, budget constraints, and desired finish quality. For small-scale projects or detailed work, handheld tools like angle grinders equipped with diamond blades offer precision and control. Larger operations, such as those found in factories producing countertops or flooring tiles, rely on more robust machinery like bridge saws or water jet cutters. These machines provide speed and efficiency while maintaining high standards of accuracy.

Maintenance of Granite Stone Cutting Tools

To ensure longevity and optimal performance from granite stone cutting tools, proper maintenance is crucial. Regular cleaning removes debris that can dull blades or impair function. Lubricating moving parts helps prevent wear and tear, extending the life of your equipment. Additionally, storing tools in a dry environment protects against rust and corrosion. For diamond-tipped tools specifically, avoiding contact with other hard surfaces when not in use preserves their sharpness.

Advancements in Granite Stone Cutting Technology

The field of granite stone cutting tools continues to advance with new technologies emerging regularly. One significant development has been the improvement in diamond blade technology. Modern blades are engineered with advanced formulations that enhance cutting speed and reduce wear. Another exciting innovation involves the integration of CNC (Computer Numerical Control) systems into cutting machinery, allowing for unparalleled precision and repeatability in complex designs.

Safety Considerations When Using Granite Stone Cutting Tools

Safety should always be a top priority when operating granite stone cutting tools. Personal protective equipment (PPE) such as safety glasses, dust masks, and hearing protection is essential. Employers must also ensure that all operators receive thorough training on the correct use and handling of these powerful tools. Implementing regular safety audits can help identify potential risks and promote a culture of caution within the workplace.

Environmental Impact of Granite Stone Cutting Tools

As awareness grows around environmental sustainability, the industry is increasingly looking at ways to reduce the ecological footprint associated with granite stone cutting tools. Manufacturers are developing more energy-efficient machines and exploring recyclable materials for tool construction. Furthermore, water recycling systems used in conjunction with wet cutting methods help minimize water usage and prevent harmful dust particles from entering the air.

The Future of Granite Stone Cutting Tools

Looking ahead, we can expect further innovations in granite stone cutting tools designed to improve efficiency, safety, and sustainability. Research into nanotechnology may lead to the creation of even stronger, longer-lasting cutting surfaces. Meanwhile, advancements in artificial intelligence could result in smarter, more autonomous cutting systems capable of learning and adapting to specific job requirements. As the industry continues to evolve, one thing remains certain: the importance of high-quality, reliable tools will never diminish.

Request for Quotation

报错: 未找到这个表单