The Releated Products of Granite Stone Cutting Blade

Granite Stone Cutting Blade

Understanding Granite Stone Cutting Blades: Precision and Durability

In the world of construction and stonework, precision and durability are paramount. Granite stone cutting blades have become indispensable tools for professionals seeking to achieve these qualities. These specialized tools are designed specifically for cutting through one of nature’s hardest materials—granite. By understanding their composition, types, and applications, users can better select and utilize these blades for optimal performance.

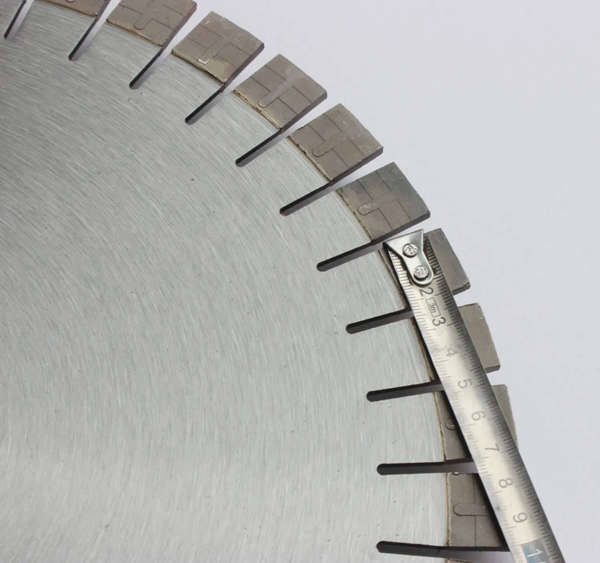

Diamond Segments: The Heart of Granite Stone Cutting Blades

The key component of granite stone cutting blades is the diamond segment. Composed of industrial diamonds embedded in a metal matrix, these segments are responsible for the actual cutting action. The quality and concentration of diamonds, along with the type of bond used, significantly affect the blade’s lifespan and cutting efficiency. Higher-quality diamonds and stronger bonds generally result in more durable blades capable of handling tougher jobs.

Types of Bonds Used in Granite Stone Cutting Blades

Different bonding methods are employed in the manufacturing of granite stone cutting blades, each suited to specific conditions. For instance, resin-bonded blades offer faster cutting speeds but may wear out quicker, making them ideal for softer granites or when speed is more critical than longevity. On the other hand, metal-bonded blades are known for their exceptional durability and ability to cut through extremely hard materials like granite, albeit at slightly slower speeds.

Choosing the Right Size for Your Granite Stone Cutting Blade

Selecting the appropriate size of granite stone cutting blade is crucial for both safety and efficiency. Smaller blades (4”-8”) are typically used for handheld cutters and are suitable for detailed work or tight spaces. Larger blades (10”-14”) are generally found on stationary saws and are better suited for heavy-duty tasks such as cutting slabs or countertops. Always ensure that the blade fits securely on your machine and does not exceed its maximum RPM rating.

Maintaining and Extending the Life of Your Granite Stone Cutting Blade

Proper maintenance can greatly extend the life of your granite stone cutting blade. After each use, clean the blade thoroughly to remove any debris that could interfere with its performance. Store it in a dry place away from direct sunlight and extreme temperatures. Periodically inspect the blade for signs of wear or damage; replace immediately if any issues are detected. Following these simple steps will help keep your blade in top condition, ensuring consistent results over time.

Applications of Granite Stone Cutting Blades in Modern Construction

From architectural projects to home renovations, the applications of granite stone cutting blades are vast. They are essential for fabricating kitchen countertops, bathroom vanities, and flooring tiles. Additionally, they play a pivotal role in monument construction and sculpture carving, where precision and accuracy are paramount. As demand for natural stone continues to rise, so too does the importance of reliable cutting tools like these specialized blades.

Advancements in Technology Impacting Granite Stone Cutting Blades

Technological advancements have led to improvements in the design and functionality of granite stone cutting blades. Innovations such as laser-welded segments and vacuum brazing techniques have enhanced blade strength and stability. Furthermore, the development of wet/dry cutting options allows for versatility depending on the project requirements and environmental considerations. These technological leaps ensure that professionals have access to increasingly efficient and effective tools for their craft.

By considering factors such as diamond quality, bond type, blade size, maintenance practices, application areas, and technological trends, users can make informed decisions when selecting granite stone cutting blades. This knowledge not only contributes to achieving superior results but also maximizes the value and longevity of this critical piece of equipment.

Request for Quotation

报错: 未找到这个表单