The Releated Products of Granite Slab Edge Cutting Machine

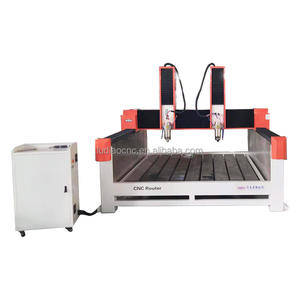

Granite Slab Edge Cutting Machine

Table of Contents

Granite Slab Edge Cutting Machine: Precision and Efficiency in Stone Crafting

In the world of stone fabrication, precision and efficiency are paramount. One machine that stands out for its ability to deliver both is the granite slab edge cutting machine. This versatile tool has revolutionized the way granite and other natural stones are processed, offering unparalleled accuracy and speed. Whether you’re a seasoned professional or new to the industry, understanding the capabilities and benefits of these machines can significantly enhance your operations.

The Importance of Granite Slab Edge Cutting Machines in Modern Workshops

The importance of granite slab edge cutting machines cannot be overstated. They play a critical role in transforming raw slabs into polished countertops, vanity tops, and other custom stone pieces. By automating what was once a labor-intensive process, these machines have enabled fabricators to increase productivity while maintaining high standards of quality.

Key Features of Advanced Granite Slab Edge Cutting Machines

Advanced granite slab edge cutting machines come equipped with features designed to optimize performance. High-speed spindles, for instance, ensure rapid cutting without compromising on finish quality. CNC (Computer Numerical Control) technology allows for precise programming, enabling complex designs to be executed flawlessly. Additionally, water-jet systems help keep the workspace clean and cool, reducing wear on cutting tools.

Benefits of Using a Granite Slab Edge Cutting Machine

Using a granite slab edge cutting machine offers several key benefits over traditional methods. Perhaps most notably, it drastically reduces production time. Complex edges that once took hours can now be completed in minutes. Furthermore, the consistency achieved through automation ensures that every piece meets the same high standards, eliminating variability often associated with hand-cutting techniques.

How to Choose the Right Granite Slab Edge Cutting Machine

Choosing the right granite slab edge cutting machine involves considering several factors. First, assess your specific needs based on the types of projects you typically undertake. For example, if you frequently work with large slabs, a machine with a wider cutting range will be more suitable. Also, consider the machine’s durability and ease of maintenance. Investing in a well-built model from a reputable manufacturer can save you money in the long run by minimizing downtime and repair costs.

Maintenance Tips for Your Granite Slab Edge Cutting Machine

To keep your granite slab edge cutting machine running smoothly, regular maintenance is essential. This includes cleaning the machine thoroughly after each use to remove any debris that could cause damage. Lubricating moving parts regularly helps prevent wear and tear. Additionally, inspecting and replacing worn blades promptly ensures optimal performance and safety.

Applications of Granite Slab Edge Cutting Machines Beyond Basic Countertops

While granite slab edge cutting machines excel at producing standard countertop edges, their applications extend far beyond this basic function. With the right attachments and programming, these machines can create intricate moldings, detailed engravings, and even three-dimensional sculptures. This versatility makes them invaluable assets for artists and designers looking to push the boundaries of what’s possible with stone.

In conclusion, the granite slab edge cutting machine represents a significant leap forward in stone fabrication technology. Its ability to combine speed, precision, and versatility makes it an indispensable tool for anyone working with granite or similar materials. As the industry continues to evolve, innovations in these machines will undoubtedly play a crucial role in shaping its future.

Request for Quotation

报错: 未找到这个表单