The Releated Products of Granite Saw Cutter

Granite Saw Cutter

Table of Contents

Granite Saw Cutter: Precision and Power in Stone Cutting

When it comes to cutting granite, precision and power are paramount. A granite saw cutter is specifically designed to handle the toughest stone cutting tasks, ensuring clean cuts and efficient performance. Whether you’re working on large-scale construction projects or intricate countertop fabrication, choosing the right granite saw cutter can make all the difference.

Choosing the Right Granite Saw Cutter

Selecting the best granite saw cutter for your needs involves considering several factors, including blade size, motor power, and water cooling systems. For instance, a larger blade diameter allows for deeper cuts, making it ideal for thicker materials. Additionally, a more powerful motor ensures that the granite saw cutter can maintain optimal speed even when faced with dense granite.

Maintaining Your Granite Saw Cutter

Regular maintenance is crucial for keeping your granite saw cutter in top condition. This includes checking the blade for wear and tear, ensuring that the water cooling system is functioning correctly, and lubricating moving parts as necessary. Proper care not only extends the life of your granite saw cutter but also ensures consistent performance and safety during operation.

Safety Tips for Using a Granite Saw Cutter

Safety should always be a priority when operating any type of machinery, especially a granite saw cutter. Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and ear protection. Keep the work area clean and free of debris to avoid accidents. Furthermore, ensure that the granite saw cutter is properly grounded and that all guards are in place before starting the machine.

Advantages of Using a Granite Saw Cutter

The benefits of using a granite saw cutter are numerous. These machines offer unparalleled accuracy and efficiency when cutting through granite, which is known for its hardness and durability. With a granite saw cutter, fabricators can achieve precise cuts with minimal effort, leading to faster project completion times and higher quality results.

Different Types of Granite Saw Cutters

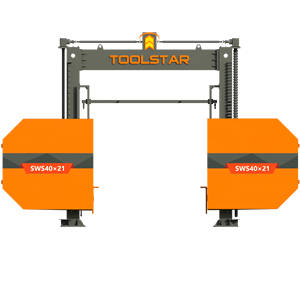

There are various types of granite saw cutters available on the market today, each suited to different applications. Bridge saws, for example, are commonly used in countertop fabrication due to their ability to make straight cuts with high precision. On the other hand, circular saws are more versatile and can be used for both straight and curved cuts, making them ideal for smaller projects or detailed work.

How to Operate a Granite Saw Cutter

Operating a granite saw cutter requires skill and practice. Start by familiarizing yourself with the controls and functions of your specific model. Adjust the blade height and position according to the thickness of the material being cut. Turn on the water supply to keep the blade cool and reduce dust. Finally, slowly guide the material through the blade, maintaining a steady pace to ensure a clean cut.

By understanding how to choose, maintain, and safely operate a granite saw cutter, professionals can achieve outstanding results in their projects. Whether you’re new to the world of stone cutting or looking to upgrade your existing equipment, investing in a high-quality granite saw cutter is a step towards achieving excellence in craftsmanship.

Request for Quotation

报错: 未找到这个表单