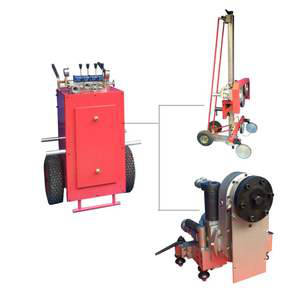

The Releated Products of Granite Rock Cutting Machine

Granite Rock Cutting Machine

Table of Contents

Granite Rock Cutting Machine: Precision, Power, and Performance

In the realm of construction and stone processing, precision and efficiency are paramount. One tool that has revolutionized the industry by meeting these demands is the granite rock cutting machine. This powerful piece of equipment offers unparalleled capabilities for cutting through one of nature’s hardest materials—granite. Let’s explore the key features, benefits, and applications of this indispensable machinery.

Advantages of Using a Granite Rock Cutting Machine

Granite rock cutting machines provide several advantages over traditional methods. Firstly, they ensure precise cuts thanks to advanced technologies like laser-guided systems. Secondly, these machines can handle large volumes of work quickly, making them ideal for commercial projects where time is money. Lastly, because they minimize waste, they are more environmentally friendly compared to manual cutting techniques.

Types of Granite Rock Cutting Machines

There are various types of granite rock cutting machines available on the market today, each designed for specific tasks. For instance, bridge saws are commonly used in fabricating countertops due to their versatility and accuracy. Wire saws, on the other hand, excel in quarrying operations, capable of slicing through massive blocks of granite with minimal effort. Understanding the differences between these models helps in choosing the right tool for your project.

Maintenance Tips for Your Granite Rock Cutting Machine

To keep your granite rock cutting machine running smoothly, regular maintenance is essential. This includes checking the blade regularly for wear and tear, ensuring all moving parts are lubricated, and keeping the machine clean after each use. By following these simple steps, you can extend the lifespan of your equipment significantly while maintaining optimal performance levels.

Innovations in Granite Rock Cutting Technology

Recent advancements in technology have led to the development of new and improved granite rock cutting machines. Features such as automated systems reduce human labor requirements while increasing productivity. Moreover, innovations in blade design have resulted in longer-lasting products that require less frequent replacement, further reducing operational costs.

Safety Considerations When Operating a Granite Rock Cutting Machine

Safety must always come first when operating any heavy machinery. Operators of granite rock cutting machines should undergo comprehensive training to understand potential hazards and how to mitigate them. Essential safety gear includes eye protection, hearing protection, and respiratory masks to guard against dust inhalation. Implementing strict safety protocols not only protects workers but also ensures compliance with industry standards.

Choosing the Right Granite Rock Cutting Machine for Your Needs

Selecting the appropriate granite rock cutting machine depends largely on the scope of your project and budget constraints. Consider factors like the size of the material you’ll be working with, the complexity of the cuts required, and the frequency of use. Consulting with experts in the field can provide valuable insights into which model best suits your specific requirements.

By investing in a high-quality granite rock cutting machine, businesses can achieve superior results while streamlining their operations. Whether you’re involved in construction, landscaping, or countertop fabrication, this versatile tool stands ready to transform the way you work with granite.

Request for Quotation

报错: 未找到这个表单