The Releated Products of Granite Molding Blade

Granite Molding Blade

Table of Contents

Understanding the Granite Molding Blade: A New Era in Precision Cutting

In the dynamic world of industrial cutting, the introduction of the granite molding blade has marked a significant advancement. This specialized tool is designed to achieve unparalleled precision and durability when working with granite and other hard materials. Its innovative design and material composition make it a game-changer for manufacturers and craftsmen alike, enhancing both efficiency and quality.

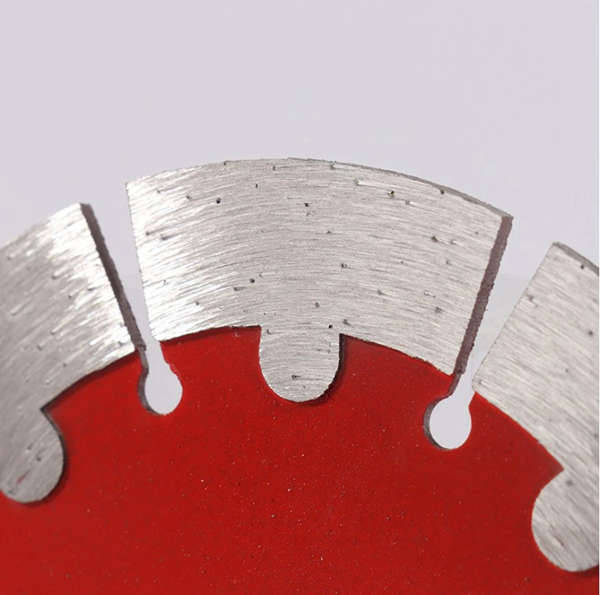

The Composition of Granite Molding Blades

The core of a granite molding blade lies in its composition. Typically, these blades are made from high-quality steel or diamond-infused materials, which are specifically chosen for their ability to withstand the abrasive nature of granite. The diamond segments, embedded around the perimeter, ensure that the blade can cut through even the toughest surfaces with minimal wear and tear. This composition not only extends the lifespan of the blade but also ensures clean, precise cuts every time.

Applications of Granite Molding Blades

From countertop fabrication to intricate stone sculptures, the granite molding blade finds application across various industries where precision and durability are paramount. In construction, these blades are indispensable for creating custom edges on countertops, which require a level of detail that standard blades cannot provide. Additionally, artisans and sculptors rely on the blade’s ability to produce fine details without chipping or cracking the material.

Advantages of Using a Granite Molding Blade

When compared to traditional blades, the granite molding blade offers several advantages that make it a preferred choice among professionals. Firstly, its ability to maintain sharpness over extended periods reduces downtime for resharpening. Secondly, the blade’s robust design minimizes vibrations during operation, leading to smoother cuts and reduced operator fatigue. Lastly, the versatility of these blades allows them to be used on multiple types of stone, making them a cost-effective investment for businesses dealing with various materials.

Maintenance Tips for Granite Molding Blades

To ensure optimal performance and longevity, proper maintenance of your granite molding blade is essential. Regular cleaning with a soft brush and water helps remove any debris that might accumulate between the segments. Avoid using harsh chemicals as they can damage the blade’s surface. It’s also important to store the blade in a dry place when not in use to prevent rust and corrosion. Periodic inspections for wear and tear will help identify when replacement is necessary, ensuring consistent quality in all cutting tasks.

Choosing the Right Granite Molding Blade

Selecting the appropriate granite molding blade depends on several factors including the type of material being cut, the thickness of the workpiece, and the desired finish. For instance, softer granites may require a blade with fewer but larger segments to prevent clogging, whereas harder stones might benefit from finer segments for more detailed work. Consulting with a specialist or referring to manufacturer guidelines can help determine the best blade configuration for specific applications.

Future Innovations in Granite Molding Blades

As technology continues to evolve, so too does the design of the granite molding blade. Researchers are exploring new materials and manufacturing processes that could further enhance the blade’s cutting capabilities. Some advancements include the development of self-sharpening mechanisms and coatings that reduce friction, leading to cooler operating temperatures and longer operational life. These innovations promise to push the boundaries of what’s possible in the realm of stone cutting and shaping.

By embracing the latest advancements in granite molding blade technology, manufacturers and artisans can achieve higher levels of productivity and craftsmanship. Whether you’re a seasoned professional or just starting out, investing in quality tools like these blades is an investment in your craft’s future.

Request for Quotation

报错: 未找到这个表单